No setor têxtil moderno, tecnologia de revestimento de tecido tem sido amplamente utilizado em tecidos funcionais, tecidos industriais, têxteis para o lar, materiais médicos e outros campos. Para atingir os objetivos de desempenho, como maciez, impermeabilidade, resistência a manchas, respirabilidade, facilidade de uso da pele, resistência à lavagem e antibacteriano, como selecionar produtos químicos para revestimento de tecidos cientificamente é a questão central que os fabricantes precisam considerar. Como um fornecedor líder de auxiliares têxteis, BLUELAKECHEM tem o compromisso de fornecer soluções químicas de revestimento de tecido de alto desempenho para clientes globais.

Como funcionam os produtos químicos para revestimento de tecidos?

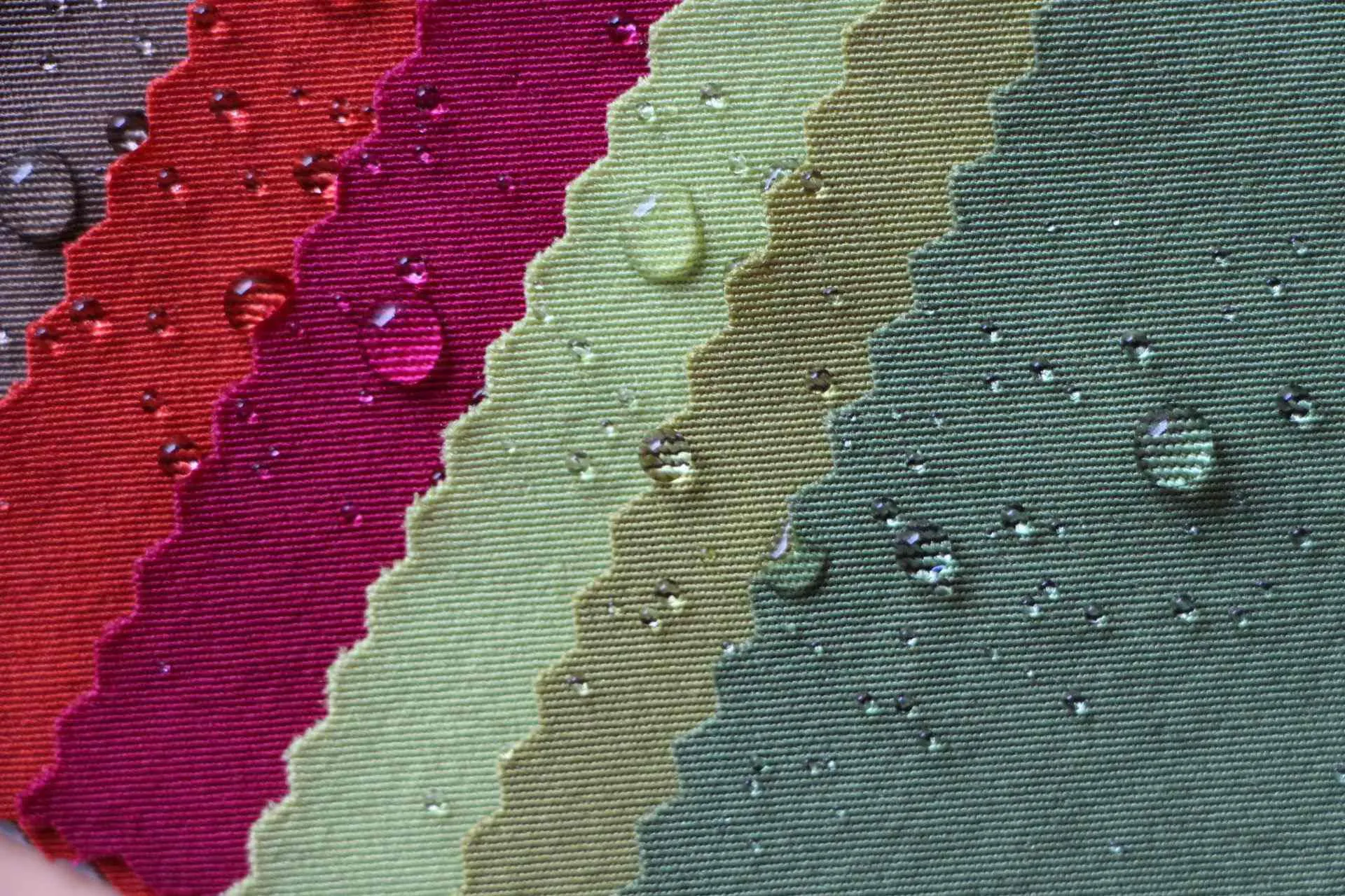

Produtos químicos para revestimento de tecidos são aditivos que podem formar uma "película protetora" funcional na superfície dos tecidos. Os usos comuns incluem imersão, raspagem, pulverização, etc., para permitir que os componentes químicos adiram e se fixem na superfície das fibras, dando ao tecido uma função específica. Por exemplo:

- Revestimento à prova d'águaO sistema de controle de qualidade de água: usa moléculas à base de silício ou flúor para formar uma estrutura hidrofóbica que torna as gotículas de água impermeáveis.

- Revestimento macio: Óleo de silicone são usadas para "lubrificar" a superfície da fibra e melhorar a sensação.

- Revestimento hidrofílico: Os grupos hidrofílicos melhoram a absorção de umidade e a respirabilidade para aumentar o conforto da pele.

- Revestimento antimicrobianoForma uma barreira antimicrobiana ativa na superfície do tecido para inibir o crescimento de bactérias.

Quatro pontos principais a serem considerados ao selecionar um produto químico para revestimento têxtil

- Primeira função: Esclareça o efeito têxtil que você deseja obter: macio, à prova d'água, antibacteriano etc.

- Combinação de tecidos: Diferentes materiais de fibra são adequados para diferentes aditivos. Por exemplo, o óleo de silicone hidrofílico é recomendado para produtos de algodão.

- Correspondência de processos: Considere o equipamento e o método de revestimento e selecione o produto com viscosidade e estabilidade adequadas.

- Proteção e certificação ambientalSe o produto precisa ser aprovado nos padrões OEKO-TEX, ZDHC e outros. A Blue Lagoon pode fornecer produtos de apoio relacionados.

Selecione os produtos químicos para revestimento de tecidos de acordo com o desempenho desejado

Diferentes requisitos funcionais determinam o tipo de produto químico de revestimento que você deve usar.

| Funcional | Tipo recomendado | Breve descrição do princípio | Aplicar efeitos |

| Macio e suave | Silicones (óleos de silicone amino) | A estrutura molecular forma uma película lubrificante na superfície da fibra, reduzindo o coeficiente de atrito | Flexível, antiestático, adequado para tecidos de algodão/poliéster. |

| À prova d'água e resistente a manchas | Emulsões de silicone | Os grupos hidrofóbicos repelem a umidade e as manchas de óleo para criar uma camada à prova d'água. | Eficiente à prova d'água e resistente a manchas, adequado para tecidos de uso externo. |

| Hidrofílico e respirável | Óleo de silicone hidrofílico | Funcionalmente equilibrado, adequado para roupas esportivas e jeans. | Melhora o conforto, geralmente usado em roupas íntimas, roupas de bebês e crianças. |

| Altamente elástico e lavável | Bloquear o óleo de silicone | A combinação da seção macia com a seção de suporte aumenta a capacidade de lavagem. | Funcionalmente equilibrado, adequado para roupas esportivas e jeans. |

| Ecologicamente correto e não tóxico | Amaciante de silicone | Emulsão à base de água, sem voláteis prejudiciais (VOCs). | Aprovado na certificação OEKO-TEX, ZDHC. |

Selecione os produtos químicos de revestimento têxtil de acordo com o material do tecido

Produtos químicos para revestimento de tecidos não são uma panaceia, e diferentes materiais de tecido têm diferentes requisitos para sistemas de revestimento devido a diferentes estruturas e atividades de superfície:

- Mistura de algodão/poliéster e algodão: boa adaptabilidade, recomenda-se usar óleo de silicone amino ou óleo de silicone hidrofílico para melhorar a maciez e a absorção de umidade.

- Nylon/Poliéster: Recomenda-se escolher um óleo de silicone em bloco que é altamente compatível com a polaridade do poliéster.

- Tecidos funcionais (como externas e médicas): à prova d'água + antibacteriano + durabilidade precisam ser considerados de forma abrangente, e soluções compostas multifuncionais são recomendadas.

BLUELAKECHEM pode fornecer portfólio de produtos auxiliares têxteis recomendações com base em seu tipo específico de tecido para garantir a adesão uniforme e o desempenho estável do revestimento.

Selecionar produtos químicos de revestimento têxtil de acordo com os parâmetros do processo

O revestimento de tecido não é apenas uma seleção química, mas um processo de correspondência de processos. Os métodos comuns de revestimento incluem imersão, raspagem, revestimento por transferência, etc. Cada processo tem requisitos diferentes de resistência ao calor, adaptabilidade de pH e estabilidade da emulsão do produto.

- Processo de impregnaçãoEmulsão: a emulsão do produto precisa ter alta estabilidade, baixa formação de espuma e forte fluidez.

- Método de raspagemRequer-se que o líquido de revestimento tenha viscosidade moderada, boa capacidade de espalhamento e seja facilmente condensado.

- Pós-tratamento de ajuste de calor: Os aditivos de revestimento precisam ser resistentes a altas temperaturas e não amarelam.

Vantagens do produto BLUELAKECHEM

Fórmula de alta concentração e baixo amarelamento, adequada para equipamentos de impregnação de alta velocidade.

Excelente estabilidade da emulsão, sem estratificação após agitação prolongada e evitando o entupimento do bocal

A excelente compatibilidade pode ser usada em combinação com resinas, retardadores de chama, agentes antibacterianos e outros aditivos

Nossa equipe técnica pode ajudar os clientes a otimizar a dosagem e as condições de revestimento para obter uma situação vantajosa tanto para o custo quanto para o desempenho.

Por que escolher a solução química para revestimento de tecidos da BlLULAKECHEM?

Como um fornecedor confiável de produtos químicos para revestimento de tecidos, BLUELAKECHEM oferece a seus clientes:

Um portfólio de silicones de alto desempenho e aditivos funcionais.

Suporte técnico de P&D, fornecendo desenvolvimento de fórmulas personalizadas.

Cumprir as regulamentações ambientais internacionais (OEKO-TEX, ZDHC, REACH, etc.).

Mecanismo de entrega flexível para dar suporte à prova rápida e aos serviços de logística internacional.

Se você é uma fábrica de tecidos para vestuário, uma fábrica de têxteis-lar ou uma empresa de exportação de vestuário, podemos fornecer soluções de revestimento de tecidos eficientes, estáveis e ecologicamente corretas. Fique à vontade para Entre em contato conosco para obter amostras e sugestões de formulação.