Hydrophilic Silicone Finishing Agent Bestowing Softness, Smoothness, Fluffiness and Bulkiness on Fabrics

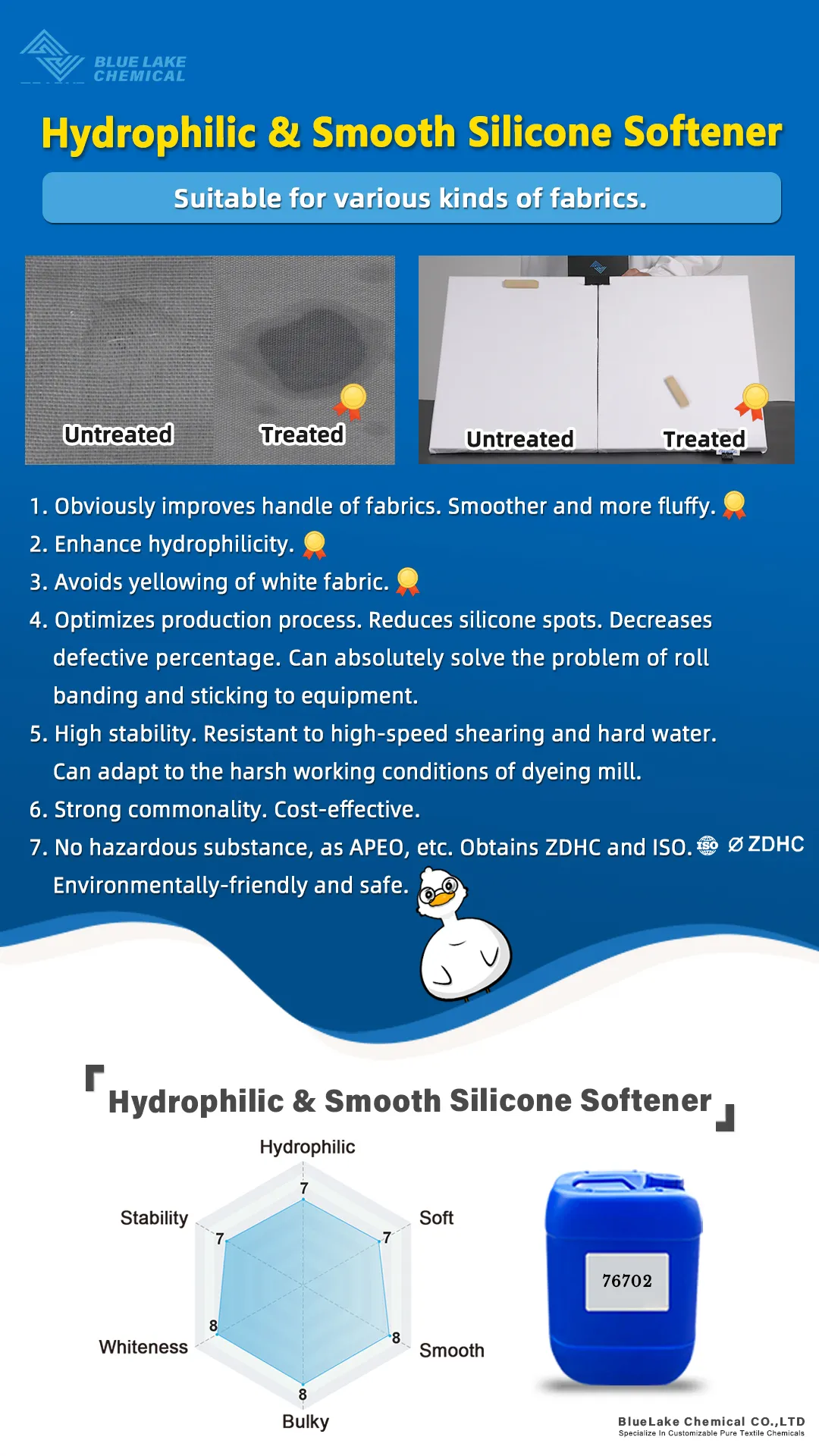

Silicone Softener 76702 is the latest special linear modified hydrophilic silicone finishing agent.It can be applied in the hydrophilic and soft finishing process for fabrics of cotton, artificial fibers, viscose fiber, synthetic fibers (polyester and nylon) and their blends, etc., which makes fabrics soft, smooth, fluffy and bulky.Oeko-Tex Standard 100 compliant. Contact us for free samples or expert guidance on formulas!

Model No. 76702

ٹیکسٹائل کیمیکل مینوفیکچرر سے

Textile Chemicals Description

Hydrophilic Silicone Oil Features:

- Contains no APEO or prohibited chemical substances. Fits environmental protection requirements. Consistent with the European Union standard of Otex-100.

- Excellent initial hydrophilicity on cellulose fibers, regenerated fiber and synthetic fiber.

- Imparts fabrics soft, smooth and fluffy handle.

- Low yellowing and low shade changing. Almost no influence on color fastness.

- Self-emulsifying property, which can ensure the stability of the bath.

- High stability. Stable in alkali, salt and anions. Keeps excellent stability under different pH value and temperature.

- Has good affinity for various kinds of textile.

- Suitable for padding and exhaust process both.

Hydrophilic Silicone Oil Applications:

It can be applied in the hydrophilic and soft finishing process for fabrics of cotton, artificial fibers, viscose fiber, synthetic fibers (polyester and nylon) and their blends, etc., which makes fabrics soft, smooth, fluffy and bulky.

Hydrophilic Silicone Oil Properties:

| ظاہری شکل: | Transparent liquid |

| Ionicity: | Nonionic |

| pH قدر: | 5.0~7.0 (1% aqueous solution) |

| حل پذیری: | پانی میں حل پذیر |

Hydrophilic Silicone Oil Instruction:

1.It is high concentration product. Kindly suggest to dilute it by 1:3 with deionized water and then use.

2.Padding Process:

For light and thin fabric, reference dosage of diluted 76702: 10~20 g/L

For heavy and thick fabric, reference dosage of diluted 76702: 20~30 g/L

The best pH range of working solution: 6.0~7.0

Padding and dipping (Pickup: 70~90%) → 140~160℃×60~90 seconds

3.Exhaust Process:

Reference dosage of diluted 76702: 1.0~3.0% (o.w.f)

Bath ratio: 1:10

Process: 40~50℃×10~20 minutes → Dewater → Drying (80~120℃)