Dalam industri tekstil global yang sangat kompetitif saat ini, produsen menghadapi tekanan yang semakin meningkat dari meningkatnya biaya bahan baku, biaya tenaga kerja, dan persyaratan pengiriman yang lebih ketat. Dalam situasi seperti ini, stabilitas produksi dan konsistensi kain menjadi lebih penting daripada sebelumnya. Bahan pembantu tekstil bukan lagi barang habis pakai yang sederhana. Mereka memainkan peran yang menentukan dalam efisiensi pemrosesan, performa kain, dan kontrol risiko kualitas. Untuk pembeli profesional, memilih pemasok bahan pembantu tekstil yang tepat sering kali memiliki dampak jangka panjang yang lebih besar daripada memilih produk individual. Artikel ini memberikan panduan praktis yang berfokus pada pembeli tentang faktor-faktor utama yang harus dipertimbangkan ketika mengevaluasi pemasok bahan pembantu tekstil.

Faktor 1: Sistem Produk Lengkap yang Meliputi Seluruh Proses Tekstil

Produksi tekstil adalah proses yang berkelanjutan dan sangat saling terkait, biasanya meliputi pretreatment, pewarnaan, dan finishing. Masalah yang timbul dalam satu tahap sering kali memengaruhi proses selanjutnya. Ketika alat bantu tidak terkoordinasi dengan baik, produsen mungkin menghadapi hasil pemrosesan yang tidak stabil, tingkat pengerjaan ulang yang meningkat, dan kualitas kain yang tidak konsisten.

Dari perspektif pembelian, bekerja sama dengan pemasok yang menawarkan alat bantu untuk seluruh proses tekstil membantu mengurangi fragmentasi pemasok, biaya komunikasi, dan risiko coba-coba. Pemasok yang ideal harus menyediakan rangkaian lengkap alat bantu pretreatment, alat bantu pencelupandan agen finishing, dan mampu mengoptimalkan formulasi dari perspektif proses.

BlueLakeChem berfokus pada bahan pembantu tekstil yang mencakup seluruh proses produksi. Dengan memahami kebutuhan proses pelanggan secara keseluruhan, Blue Lake memberikan solusi terintegrasi daripada rekomendasi produk yang terisolasi.

Faktor 2: Stabilitas Produk dan Konsistensi Batch

Stabilitas produk adalah salah satu perhatian paling penting bagi pembeli bahan pembantu tekstil. Bahkan sedikit variasi di antara batch dapat menyebabkan perbedaan yang nyata dalam rasa kain, keseragaman warna, atau kinerja finishing, sehingga meningkatkan risiko klaim kualitas dan kerugian produksi.

Saat menilai keandalan pemasok, pembeli harus memperhatikan sistem manajemen mutu, konsistensi bahan bakudan prosedur pengujian batch. Performa produk yang stabil tidak hanya memastikan hasil produksi yang konsisten, tetapi juga mengurangi kebutuhan akan penyesuaian proses yang sering dilakukan.

Kami mengikuti prosedur manufaktur dan kontrol kualitas yang terstandardisasi, memastikan bahwa bahan pembantu tekstil mempertahankan kinerja yang konsisten di seluruh batch dan siklus produksi yang berbeda.

Faktor 3: Kemampuan Adaptasi Teknis terhadap Kain dan Proses yang Berbeda

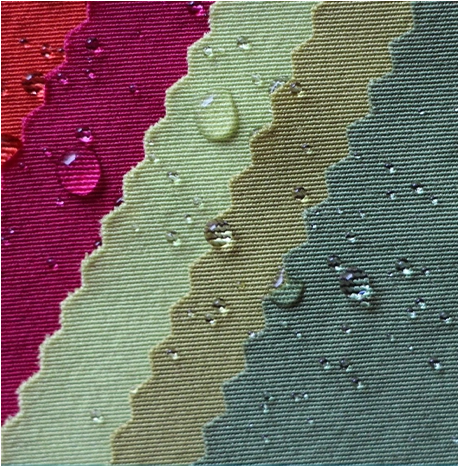

Serat dan struktur kain yang berbeda memberikan tuntutan yang sangat berbeda pada bahan pembantu tekstil. Kain katun, poliester, nilon, dan kain campuran sangat bervariasi dalam hal daya serap, afinitas pewarna, dan perilaku finishing. Akibatnya, solusi tambahan satu ukuran untuk semua jarang efektif.

Pemasok yang cakap harus mampu menyesuaikan sistem tambahan dengan jenis kain tertentu, kondisi pemrosesan, dan target kinerja. Hal ini membutuhkan pemahaman yang kuat tentang karakteristik serat, mekanisme pencelupan, dan teknologi finishing.

Sebagai produsen bahan pembantu tekstil terkemuka, BlueLakeChem menawarkan portofolio yang terdiversifikasi dari silikon-berbasis dan alat bantu fungsional, termasuk minyak silikon amino, pelembut silikon hidrofilik, dan minyak silikon blok. Produk-produk ini dapat disesuaikan dengan berbagai jenis kain dan persyaratan aplikasi untuk mencapai hasil yang optimal.

Faktor 4: Ketersediaan Dukungan Teknis dan Panduan Aplikasi

Dalam produksi tekstil di dunia nyata, masalah terkait bahan pembantu seperti pembusaan, sedimentasi, penguningan, atau ketidakcocokan adalah hal yang umum terjadi. Jika pemasok hanya menyediakan produk tanpa dukungan teknis, pembeli harus menanggung biaya uji coba berulang kali dan gangguan produksi.

Pemasok bahan pembantu tekstil profesional harus memberikan dukungan teknis yang berkelanjutan, membantu pelanggan mengidentifikasi akar masalah dan mengoptimalkan parameter pemrosesan. Dukungan ini secara signifikan mengurangi risiko produksi dan meningkatkan efisiensi secara keseluruhan.

Selain memasok produk, kami menekankan bantuan teknis tingkat aplikasi, menawarkan rekomendasi proses dan analisis masalah untuk membantu pelanggan menstabilkan produksi dan meningkatkan kualitas output.

Faktor 5: Kemampuan Optimasi Kustomisasi dan Formulasi

Dengan meningkatnya permintaan untuk tekstil fungsional dan kain kelas atas, produk tambahan standar sering kali tidak mencukupi. Solusi yang disesuaikan menjadi sangat penting ketika berhadapan dengan kain khusus, persyaratan sentuhan tangan yang unik, atau pesanan ekspor berstandar tinggi.

Pembeli harus mengevaluasi apakah pemasok dapat menyesuaikan formulasi, menyediakan pengambilan sampel skala laboratorium, dan merespons dengan cepat terhadap kebutuhan aplikasi tertentu. Kemampuan penyesuaian mencerminkan kedalaman teknis dan potensi kemitraan jangka panjang pemasok.

Kami mendukung penyesuaian formulasi yang berorientasi pada kinerja berdasarkan kebutuhan pelanggan, memberikan solusi yang lebih selaras dengan kondisi produksi aktual.

Faktor 6: Kepatuhan terhadap Peraturan Lingkungan Hidup dan Standar Pasar Ekspor

Kepatuhan terhadap lingkungan telah menjadi persyaratan yang tidak dapat dinegosiasikan di pasar tekstil internasional. Peraturan seperti REACH dan OEKO-TEX memberlakukan batasan yang ketat pada bahan kimia tekstil, dan ketidakpatuhan dapat mengakibatkan penolakan pengiriman atau hambatan akses pasar.

Pembeli sebaiknya tidak hanya menilai status kepatuhan pemasok saat ini, tetapi juga mempertimbangkan komitmen jangka panjang mereka terhadap pengembangan produk yang berkelanjutan dan bertanggung jawab terhadap lingkungan.

BlueLakeChem terus berinvestasi dalam pengembangan bahan pembantu tekstil yang lebih ramah lingkungan dan efisien, sehingga memungkinkan pelanggan untuk memenuhi persyaratan peraturan sambil mempertahankan standar kinerja yang tinggi.

Faktor 7: Keandalan Pasokan dan Nilai Kemitraan Jangka Panjang

Pengadaan bahan pembantu tekstil bukanlah transaksi satu kali, melainkan upaya kerja sama jangka panjang. Keandalan pengiriman, efisiensi komunikasi, dan daya tanggap pemasok secara langsung memengaruhi perencanaan produksi dan biaya operasional.

Bagi pembeli, memilih pemasok yang menghargai kolaborasi jangka panjang dan secara aktif mendukung pengoptimalan proses sering kali memberikan nilai yang lebih besar daripada memilih opsi dengan harga terendah.

BlueLakeChem, sebagai mitra yang berorientasi pada solusi jangka panjang, menyediakan pasokan yang stabil dan dukungan teknis yang berkelanjutan untuk membantu pelanggan meningkatkan daya saing dari waktu ke waktu.

Kesimpulan

Memilih pemasok bahan pembantu tekstil yang tepat adalah keputusan strategis yang secara langsung memengaruhi stabilitas produksi, konsistensi kualitas, dan daya saing jangka panjang. Daripada hanya berfokus pada harga produk, pembeli harus mengevaluasi pemasok berdasarkan kelengkapan sistem produk, kemampuan teknis, konsistensi, tingkat layanan, dan komitmen keberlanjutan.

Untuk produsen tekstil yang mencari kinerja yang andal, optimalisasi proses, dan kepatuhan terhadap persyaratan pasar global, bermitra dengan pemasok yang menawarkan solusi tambahan tekstil yang lengkap adalah investasi jangka panjang yang baik. Saya yakin bahwa BlueLakeChem adalah pilihan ideal Anda. Hubungi kami untuk menciptakan solusi alat bantu tekstil spesifik Anda!