Ultra Yumuşak Silikon Yağı Emülsiyonu, Pamuk Viskon için Sararmayı Önleyici Apre Maddesi

BLUELAKECHEM Silicone Oil Emulsion is a modified block silicone oil designed for cotton, viscose, and blended fabrics. It provides an ultra-soft handle, excellent smoothness, and outstanding anti-yellowing performance, making it the ideal finishing agent for high-quality and light-colored textiles. Contact us to request a technical data sheet, free samples, or expert advice for your bulk fabric finishing needs.

Model No.70868

Tekstil Kimyasalları Üreticisinden

Tekstil Kimyasalları Açıklama

Silikon Yağı Emülsiyonu Özellikler:

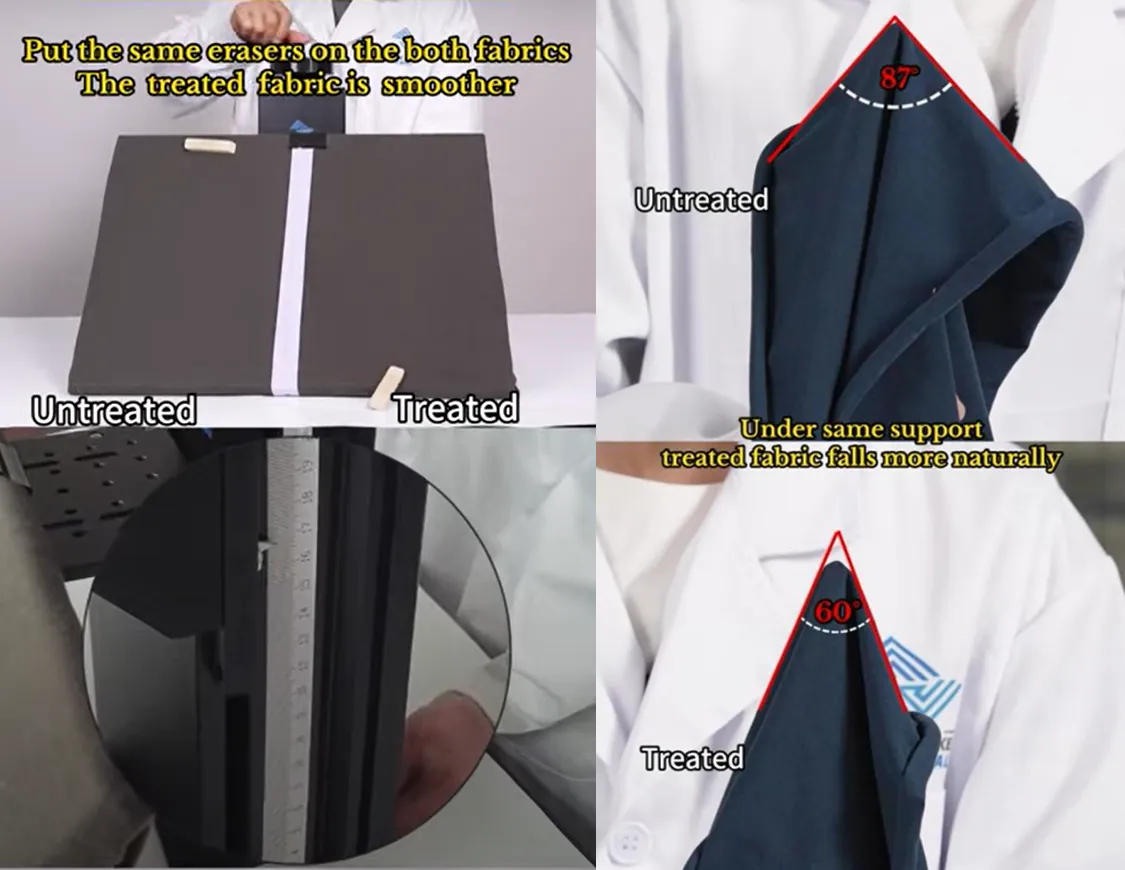

Excellent Softness & Smoothness: Gives fabrics a soft, fluffy, and premium handle without greasiness or stickiness.

Anti-yellowing Performance: Special formulation prevents yellowing even after high-temperature processing or long-term storage, ideal for light-colored and white fabrics.

High Emulsion Stability: Maintains stable dispersion and uniform finishing performance during production.

Kolay Emülsifiye Edilebilir: Geniş bir ekipman yelpazesi kullanılarak işlenebilir, böylece çok çeşitli üretim süreçlerine kolayca entegre edilebilir.

Çevre dostu ve toksik değildir: Silikon yağı emülsiyonu çevre dostudur ve ciltle doğrudan temas eden tekstiller için katı güvenlik standartlarını karşılar.

Çok Yönlü Uygulama: Pamuk ve selüloz gibi doğal elyaflara, sentetik elyaflara ve karışımlara uygulanır.

Uygulama Alanları

- Soft finishing of fabrics: Cotton, viscose, polyester, and blended fabrics

- Ev tekstili: Towels, bedding, upholstery

- Baby and premium fabrics: Provides tender yet durable softness

- Industrial textiles: Enhances handle for water-repellent or functional fabrics

- Heat-sensitive fabrics: Low-yellowing property suits light-colored or delicate textiles

Silicone Oil Emulsion Technical Parameters:

| Öğe | Specification |

| Görünüş | White or milky emulsion |

| İyoniklik | Zayıf katyonik |

| pH (1% aqueous solution) | 6.0-7.0 |

| Çözünürlük | Easily emulsified in water |

Recommended Application Methods

Padding Process:

- Light fabrics: 10–20 g/L

- Heavy fabrics: 20–30 g/L

- Stenter: 160–170 °C × 60–90 s

- pH: 6.0–7.0

Exhaust Process:

- Dosage: 1.0–3.0% (o.w.f)

- Banyo oranı: 1:20

- Temperature: 40–50 °C × 10–20 min → Dewater → Dry at 100–120 °C

Can be used together with other softeners. Perform compatibility testing before blending.