During the spinning, weaving and stentering processes of Nylon and nylon/spandex fabric, various oiling systems (including silicone oil, heavy oil and emulsifiers, etc.) are introduced. If the degreasing in the pretreatment is not thorough, it is very easy to cause quality problems such as dyeing defect, silicone spots, white spots, back staining, sticky handles, and residual odor in the subsequent dyeing and finishing process. Choosing a high-efficiency emulsifying, dispersing degreasing agent can emulsify, disperse, transfer and wash off the greasy dirt without damaging the fibers, and also inhibit secondary staining and equipment pollution, which ensures the stability of dyeing and finishing and the rate of finished products from the source.

Mechanism and election points of the nylon degreasing agent

High-quality nylon degreasing agent is usually compounded by a multi-surfactant system, including comprehensive functions, as emulsifying, dispersing, wetting, scouring and anti-fouling, etc. The greasy dirt is emulsified into fine particles and then dispersed and stabilized. Finally, they are carried away with the bath liquid. At the same time, by wetting, the capillary channels of fibers/yarns are opened up, so as to improve the elution efficiency and reduce the probability of back staining and “white spots”. For the nylon/spandex system, an excellent formula needs to particularly enhance the removal ability of spandex silicone oil, maintain mildness to elastic fibers and avoid damage to strength caused by strong alkaline or strong oxidizing conditions. The above-mentioned capabilities have been verified in mature products in the industry. For example, a certain type of formula definitely emphasizes the comprehensive performance of emulsifying, dispersing, wetting, anti-fouling and efficient degreasing.

Application scope of the nylon degreasing agent

- Nylon knitted fabrics and warp knitting fabrics: swimsuit fabric, fabric for yoga clothing and sportswear, fabric for functional underwear.

- Nylon and nylon/spandex: elastic fabric with high spandex content, close-fitting clothing.

- Polyester/spandex and chemical fiber blends: the continuous production of open-width degreasing and scouring that needs to be completed in the same bath.

- Light-colored and high-brightness fabrics that are sensitive to “white spots/silicon spots”: raw white, light beige and fluorescent color fabrics that have a high requirement for dyeing and fixing.

A mature solution can cover two major process systems: continuous open-width degreasing + scouring va cylindrical/rope-shaped intermittent degreasing in the same bath. Also, it has strong adaptability to equipment and pH conditions (Continuous open-width degreasing process can be carried out under acidic conditions, and can effectively prevent white spots and decrease the risk of polluting equipment).

Process flow and recommended dosage for degreasing nylon fabrics

1. Continuous open-width degreasing/scouring (Suitable for nylon/spandex knitted fabrics)

- Dosage: degreasing agent: 1.0~2.0 g/L, can be used together with Anti white spot agent (0.2~0.3 g/L) as needed.

- Temperature and subdivision control:First unit: 80~85℃ → Second unit: 90~95℃ → Third unit: softened water, 60℃ → Forth to seventh unit: softened water, 25℃

- Key point: can be used in an acidic condition. Focus on controlling the temperature platform and mechanical action of the first and second units, so as to ensure full emulsification and dispersion. There should be several softened water washes in the subsequent units to decrease back staining.

2. Intermittent one-bath degreasing (processed in dyeing bath)

- Dosage: degreasing agent: 1.0~2.0 g/L, can be used together with Anti white spot agent (0.2~0.3 g/L) as needed.

- Bath ratio: 1:10~1:20

- Jarayon: add into the bath at 25℃ → Increase temperature to 95~98℃

and keep for 30 minutes → Water washing for 1~2 times - Key point: adequate circulation and proper shearing are helpful to the transfer of greasy dirt. Control the temperature gradient and keep time.

The above parameters are common references. For a specific one, please make a test according to the equipment load, fabric weight and the type and content of greasy dirt. If necessary, please add anti white agent and optimize the water washing process to decrease the risk of back staining and spots.

How to improve yield and reduce common defects through degreasing agents

- Prevents white spots and silicone spots: in acid and open-width conditions, using anti white spot agent, controlling the temperature of front units and mechanical action and strengthening softened water washing in the latter units can obviously decrease the rate of white spots and silicone spots.

- Anti-fouling and clean equipment: choosing the formula that has anti-fouling ability and is not easy to pollute the equipment can decrease back staining and residue on the roller.

- Mild to fibers: avoid strong alkali or overly oxidized systems in the same bath with spandex. Choose a “mild and high-efficiency” system to effectively remove dirt without damaging the fibers.

- Identify the grease: for spandex silicone oil, chemical fiber heavy oil and oil emulsion dressing, etc., it needs to choose the formula that has a specific ability to remove silicone oil, and optimize the dosage through microscopic and surface tension tests.

Key technical parameters and performance data of nylon degreaser

- Tashqi ko'rinishi: light yellow transparent liquid, Ionlik: Nonionic, pH value (1% aqueous solution): 7.0±1.0, Solubility in water: Good

- Performance: high-efficiency degreasing. Multiple functions of emulsifying, dispersing, wetting, scouring and anti-fouling. Excellent ability to remove spandex silicone oil.

- Applicable processes: open-width continuous degreasing and scouring, intermittent one-bath degreasing. It can be used in an acidic condition and also balances the cleanliness of the equipment.

The above indicators are from the data sheets of mature products and are only for engineers’ selection and comparison reference.

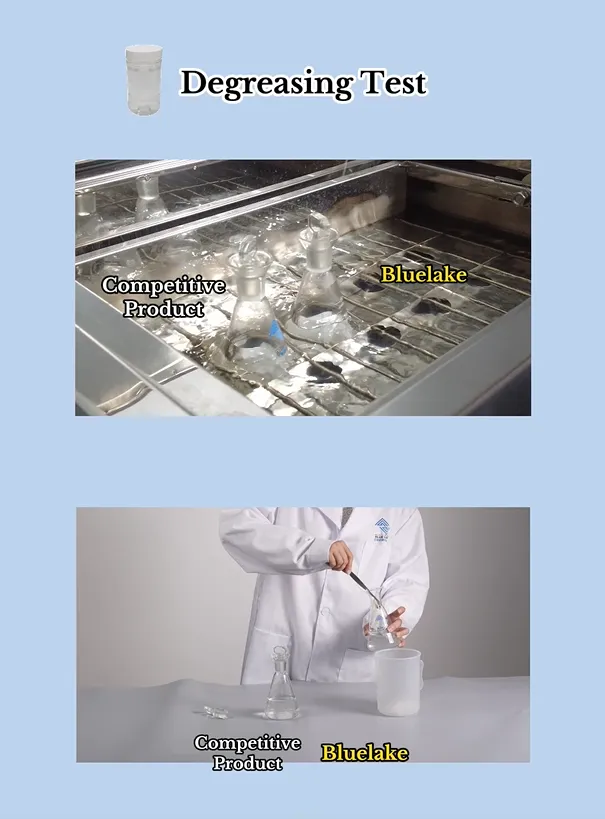

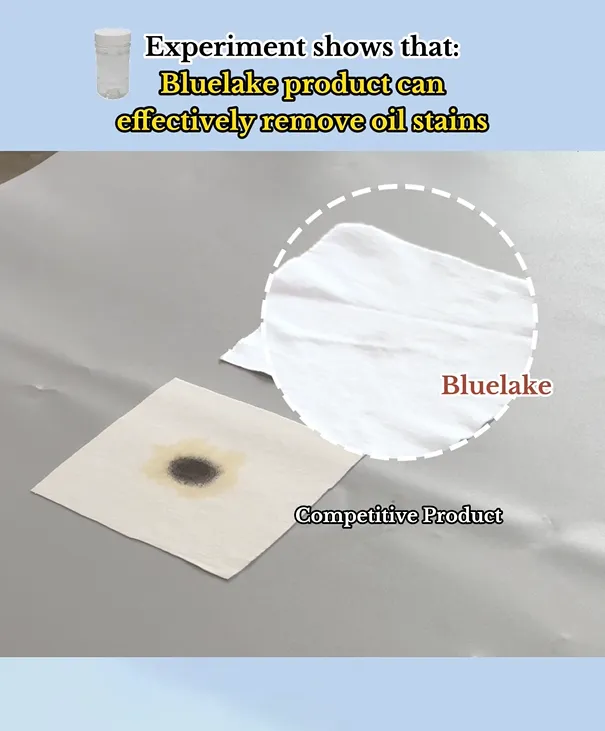

Recommend product: 11003 nylon degreasing agent

11003 Nylon Degreasing Agent, specifically created for nylon and nylon/spandex systems, is compounded with various kinds of surfactants. In the open-width continuous process and intermittent one-bath process, it performs high-efficiency degreasing and excellent anti-staining performance. It has outstanding emulsifying, dispersing and removing ability on spandex silicone oil, chemical fiber heavy oil and oil emulsion dressing. And it can have open-width continuous degreasing under acid conditions, which can effectively prevent white spots without polluting the equipment. Its typical state is light yellow transparent liquid, nonionic and pH (1%) 7±1. Reference dosage is 1~2 g/L.

The open-width temperature is suggested to be controlled within 80~95℃ sectionally.

For an intermittent process, it can be processed at 95~98℃ and kept for 30min, then washed with softening water.

Xulosa

Nylon and nylon/spandex fabrics face problems such as oil residue, white spots, and silicone spots during the dyeing and finishing process, often leading to product rework and reduced yield. Choosing a nylon degreasing agent with efficient emulsifying, dispersing, wetting, and anti-fouling properties not only effectively removes spandex silicone oil and heavy oil but also prevents equipment contamination, ensuring a stable dyeing and finishing process.

BLUELAKECHEM has been focusing on researching, developing and applying textile auxiliaries. Our products include pretreatment, dyeing and finishing, etc. We provide technical support for overseas dyeing and finishing enterprises and distributors, from small-scale trial evaluation, process scale-up, to on-site optimization. If you need a 11003 Nylon Degreasing Agent sample and solution, please contact us to gain a higher-efficiency and more stable nylon degreasing solution.