In the textile dyeing and finishing industry, “white” is not only a color, but also a symbol of quality. Especially in the field of high-end cotton products such as home textiles, underwear, shirts and children’s clothing, terminal brands and consumers have higher requirements for the whiteness, brightness and cleanliness of fabrics.

While hydrogen peroxide bleaching is effective in removing impurities and yellowing, it often cannot deliver the brilliant, vivid whiteness desired for high-end markets. This is where optical brightening agents (OBAs) become an essential finishing solution, providing optical enhancement that boosts both the appearance and market value of fabrics.

What is An Optical Brightening Agent?

Optical Brightening Agent is a type of organic fluorescent compound that can absorb ultraviolet (UV) rays and convert them into visible blue-violet light.

When it is applied to cellulose fibers, as cotton, etc., it can cover the original natural light yellow color and create a whiter and brighter visual effect by reflecting blue light. That is called physical visual compensation.

It does not chemically change the fiber color itself but creates a brighter, cleaner appearance, making it an essential finishing step for fabrics with high whiteness requirements.

Key Application Fields of Optical Brightening Agent for Cotton Fabrics

Optical Brightening Agent has a good affinity for cotton fabrics, especially suitable for the following fields:

- Fabrics with high whiteness requirement: Bed sheet, towel, T-shirt, children’s clothing and work clothes, etc.

- Printed base fabric or bleached grey fabric: Improves original color. Improves printing effect.

- Control of yellowing after the bleaching process: Prevents yellowing during transportation or storage

- Pretreatment of color-spun cotton yarns: Improves the overall visual cleanliness.

- Whitening for knitted fabrics: Keeps a bright and white effect without influencing the soft handle.

Five Core Advantages of Optical Brightening Agents:

- Improves the whiteness and brightness of fabrics. Especially suitable for products displayed in a light environment.

- Strong fluorescence & process stability. Resistant to high temperature and oxidative bleaching

- Cost-effective. A small dosage can achieve a significant whitening effect.

- Suitable for various kinds of processes. Can be used in pad dyeing, exhaust dyeing and bleaching, and finishing one-bath process, etc.

- No adverse effect on the handle. No need for additional soft finishing.

Optical Brightening Agent vs. Traditional Bleaching

| Comparing Item | Hydrogen Peroxide Bleaching | Optical Brightening Agent |

| Principle | Removes natural impurities and pigment | Absorb UV-light→Emit blue light→Visual whitening |

| Changes fiber color? | Yes | No |

| Whiteness effect | High, but a little dull | Brightly white, strong cleanliness |

| Yellowing control | Limit, fades easily over time | Good, can neutralize the slightly yellow color shade |

| Applicable stage | Pretreatment bleaching | After bleaching, finishing, and pretreatment for printing |

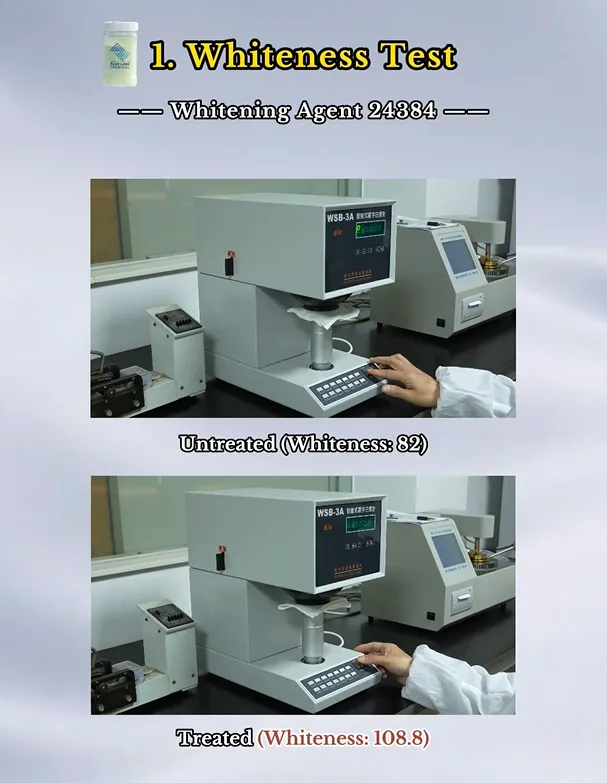

Recommended Product: 24384 Optical Brightening Powder (Suitable for Cotton)

Designed for cellulose fibers such as cotton, flax, viscose, Tencel, and Modal, BLUELAKECHEM 24384 Optical Brightening Powder meets the demanding standards of high-end fabrics.

Product Features:

- Chemical composition: Styrene derivative-based, high-intensity blue light fluorescence.

- Applicable fibers: Cotton, flax, viscose fiber, Rayon, Modal, Tencel and their blends.

- High fluorescence intensity: Even a low concentration can achieve a significant whitening effect.

- Performance: High fluorescence intensity even at low dosage; resistant to high temperature & alkali; compatible with hydrogen peroxide in the same bath

Appearance & Properties:

- Appearance: Yellow-green powder

- Ion type: Anionic

- pH (1% solution): 8.0 ± 1.0

- Solubility: Water-soluble

Reference Process:

- For exhaust process:

- Reference dosage: 0.1~0.4% (o.w.f).

- Temperature: 90~98℃

- Time: 40~60 minutes

- Can be used together with the hydrogen peroxide bleaching process in the same bath.

- Padding process:

- Reference dosage: 1~4 g/L

- Process: Dipping and padding for two times →Steaming→Drying

It is suitable for the finishing process for cone yarn, piece goods, and ready-made garments. It can be flexibly embedded in various kinds of production processes.

BLUELAKECHEM haqida

BLUELAKECHEM specializes in textile auxiliaries for pretreatment, dyeing, and finishing.

With an independent formula platform and application lab, we serve clients in Southeast Asia, the Middle East, South America, Africa, and beyond.

Our 24384 Optical Brightening Agent has been widely adopted in high-end home textiles, knitted fabrics, and printed fabrics, helping customers achieve superior whiteness and enhance brand competitiveness.

If you have a demand for Optical Brightening Agent or other dyeing and finishing auxiliaries, please contact us to get a sample or process suggestion.