En los tejidos de algodón, como textiles para el hogar de gama alta, camisas, ropa infantil y prendas ajustadas, etc., el “tacto” y la “suavidad” del tejido afectan directamente a las decisiones de compra de los consumidores finales. Los suavizantes tradicionales suelen mejorar sólo el tacto, pero pueden causar una sensación “aceitosa”, reducir la absorción de humedad de los tejidos o provocar la acumulación de colorante. Apuntando a este punto doloroso, con la ruta técnica de “Alta concentración y modificación hidrofílica”, aceite de silicona hidrófilo de alta concentración y respetuoso con la piel puede aumentar significativamente la suavidad, la tersura y la sensación de bienestar de la piel sin influir en la absorción de la humedad.

¿Por qué elegir aceite de silicona hidrófilo de alta concentración y respetuoso con la piel?

Equilibrio entre asa y función

Con las moléculas de silicona hidrófila modificada, puede formar una película uniforme, transpirable y agradable para la piel en la superficie de la fibra, que no sólo hace que el tejido sea suave, liso y seco, sino que también mantiene una buena absorción de la humedad y transpirabilidad.

Satisface la demanda de tejidos de gama alta

Al tiempo que persiguen un tacto “sedoso” y “aterciopelado”, las fibras naturales (como el algodón y el rayón, etc.) suelen exigir que el tejido no sea aceitoso, no amarillee y tenga poca diferencia de color. El suavizante de silicona de alta concentración, hidrófilo y respetuoso con la piel, se caracteriza por su bajo amarilleamiento y su escaso cambio de tono, por lo que puede satisfacer estos requisitos.

Disminuye la complejidad del fórmula

Una fórmula de alta concentración supone un menor coste de transporte y almacenamiento. Y, al mismo tiempo, puede lograr un efecto ideal con una dosis muy pequeña. Es conveniente que las fábricas lo utilicen en diferentes líneas de producción.

Principio técnico: doble garantía de hidrofilia y suavidad

Generalmente, aceite de silicona hidrófilo de alta concentración y respetuoso con la piel es un bloque modificado emulsión de silicona orgánica hidrófila. Su mecanismo de funcionamiento incluye:

- La cadena principal de silicona forma una película flexible en la superficie de la fibra para reducir el coeficiente de fricción de la superficie, aportando así un tacto “sedoso y suave”.

- Los grupos hidrófilos (como el poliéter) proporcionan sitios de afinidad para las moléculas de agua, de modo que las gotas de agua se extienden rápidamente por la superficie de las fibras y penetran en ellas, manteniendo la absorción de humedad del tejido.

- La propiedad autoemulsionante y la estabilidad de la emulsión de silicona pueden garantizar que el auxiliar se distribuya uniformemente en el relleno o el sistema de escape y evitar la acumulación o la diferencia de color.

Tejidos aplicables y escenarios típicos de aplicación

- Aplicación principal: Tejido natural o de alto algodón, como algodón, mezclas de algodón, fibra de viscosa, Tencel y Modal. Mezclas de fibras químicas.

- Uso típico: Acabado final para textiles domésticos de gama alta (sábanas y fundas de edredón), ropa infantil, camisas, ropa interior y tejidos de punto de alta calidad. También es adecuado para una línea de producción de productos acabados que requiera un bajo amarilleamiento y una alta blancura.

Principales resultados y valor comercial

- La alta concentración y la pequeña dosificación tienen un coste más económico para los ingredientes de una sola cara.

- Aumenta significativamente la suavidad y tersura de los tejidos. Confiere a los tejidos un tacto sedoso y exquisito.

- Buena hidrofilia: No disminuye la absorción de humedad original de los tejidos. Más cómodo de llevar.

- Poco amarilleo y poco cambio de tonalidad: Adecuado para tejidos de color claro y blanco intenso.

- Buena estabilidad del proceso: Puede utilizarse junto con un agente blanqueador y resina en el mismo baño (según prueba de compatibilidad).

- Fórmula respetuosa con el medio ambiente: Sin sustancias prohibidas, como APEO, etc. Puede satisfacer los requisitos de conformidad de marcas y clientes de comercio exterior.

Referencia del proceso y sugerencias de funcionamiento

Para implementar la línea de producción y copiar parámetro, los siguientes son dos referencias de proceso de acabado de uso común, como relleno y escape:

- Proceso de acolchado (recomendado para su uso en producción continua y acabado de productos acabados)

- Dosis de referencia: Tejido ligero y fino 10~20 g/L, Tejido pesado y grueso: 20~30 g/L

- pH de trabajo6,0~7,0 (neutro a ligeramente ácido)

- Proceso: Acolchado (Recogida: 70~90%)→ Secado → Stentering (160~170℃×60~90 segundos).

- Escena aplicable: Línea de producción en masa de teñido de ropa de cama, camisas y acolchados para prendas de prêt-à-porter

- Proceso de escape (Se recomienda su uso para lotes pequeños/tratamientos especiales)

- Dosis de referencia: 1,0~3,0% f.e.p.

- Proporción de baño: 1:20 (Puede ajustarse según el equipo y el proceso)

- Proceso: 40~50℃×10~20 minutos→Deshidratación →Secado (100~120℃).

- Escena aplicable: Acabado para prendas de prêt-à-porter o tejidos especiales que necesitan una humectación profunda.

Sugerencias para el funcionamiento práctico: Antes de poner en producción un producto de alta concentración, es esencial hacer una pequeña prueba de muestra (diferentes tejidos, diferente superficie del tejido después del teñido, diferente profundidad de teñido) para asegurar el tacto, la diferencia de color y la consistencia del aspecto después del secado. Cuando se utiliza junto con un agente blanqueador o resina en el mismo baño, por favor haga una prueba de compatibilidad

para evitar la influencia mutua.

Puntos principales de compatibilidad, estabilidad y control de calidad

- Prueba de compatibilidad: Si se utiliza con abrillantadores fluorescentes, resinas y suavizantes de uso común, haga una pequeña prueba para verificar que no haya emulsificación ni delaminación, que no haya sedimentación y que no haya una diferencia de color evidente.

- Resistencia al proceso: Generalmente, suavizante de silicona hidrofílica de alta concentración permanece estable en un amplio rango de pH y temperatura. Pero aún así se sugiere no mezclar directamente con oxidantes fuertes y añadir al baño.

- Control del amarilleamiento y la diferencia de color: Antes de utilizarlo para tejidos de color claro o muy blancos, es necesario confirmar el proceso de secado a baja temperatura durante poco tiempo y la dosificación de la fórmula para evitar una ligera transferencia de color.

- Almacenamiento y manipulación: Remover uniformemente antes de usar. No lo exponga al aire durante mucho tiempo. Almacenar en un lugar fresco y ventilado. La protección personal y la eliminación de residuos líquidos deben llevarse a cabo de acuerdo con el PNT de la fábrica.

- Sugerencias para el índice de pruebas: Manejabilidad (puntuación subjetiva), prueba de penetrabilidad/índice de absorción de agua, diferencia de color ΔE, prueba de amarilleamiento por calor (aceleración en horno) y prueba de solidez al lavado.

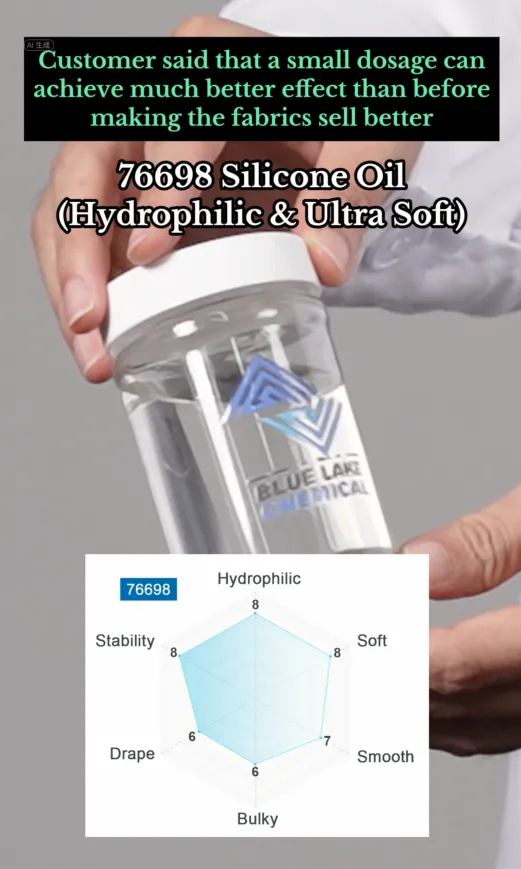

Recomendar producto: 76698 aceite de silicona de alta concentración hidrófilo y respetuoso con la piel

Para cumplir los requisitos de acabado mencionados, BLUELAKECHEM 76698 Suavizante de silicona hidrófilo y respetuoso con la piel de alta concentración es un suavizante de silicona tipo emulsión desarrollado específicamente para fibras naturales y mezclas de algodón. Este producto es una emulsión de silicona hidrófila modificada en bloque, que puede proporcionar un “tacto suave, liso y sedoso” y una buena hidrofilia a los tejidos de algodón. Tiene propiedades autoemulsionantes. Puede utilizarse junto con un agente blanqueador y resina en el mismo baño y permanece estable. Los datos tecnológicos clave y la dosificación de referencia son los siguientes (para referencia de producción):

- Apariencialíquido incoloro o amarillo claro transparente, Ionicidad: catiónico débil, Valor pH: 6,0~7,0 (1% solución acuosa), Soluble en agua

- Dosificación de referencia para el teñido de acolchadosTejido ligero y fino: 10~20 g/L, tejido pesado y grueso: 20~30 g/L, pH de trabajo: 6.0~7.0, Stenter: 160~170℃×60~90 segundos

- Dosis de referencia para el teñido por agotamiento: Dosis de referencia: 1,0~3,0% f.e.p., Relación de baño: 1:20, 40~50

℃×10~20 minutos→Deshidratación→Secado (100~120℃) - Otra característica: Buena hidrofilia en fibras naturales. Mantiene la hidrofilia original en fibras químicas. Bajo amarilleamiento y baja diferencia de color. Mantiene una alta estabilidad bajo diferentes valores de pH y temperaturas. Fácil de deslanar y fácil de reparar el color si el tejido acabado necesita ser modificado o teñido.

Acerca de BLUELAKECHEM

BLUELAKECHEM se ha centrado en la investigación, el desarrollo y la producción de auxiliares textiles. Nuestros productos incluyen pretratamiento, tintura y acabado. Nos comprometemos a proporcionar soluciones auxiliares de alta concentración, alta estabilidad y respetuosas con el medio ambiente a empresas mundiales de tintura y acabado. Y ofrecemos pruebas de muestras pequeñas, verificación en masa y asistencia técnica in situ para ayudar a los clientes a conseguir una doble mejora en la eficacia de la producción y la calidad del producto. Si necesita una muestra 76698, TDS o una fórmula experimental del proceso, por favor Contacto para obtener asistencia técnica y servicio de pruebas de muestras.