In the traditional textile production, soft finishing is usually carried out separately after dyeing or soaping. However, as the global demand for energy conservation, emission reduction and improvement of production efficiency continues to rise, more and more dyeing and finishing mills are beginning to seek soft finishing solutions that can be used in the same bath with dyeing and soaping processes.

BLUELAKECHEM has developed a one-bath hydrophilic bath softener especially designed for cotton and cotton blends. It can be added directly into the dyeing bath, soaping bath or finishing bath, while imparting softness, fluffiness and excellent hydrophilicity to fabrics.

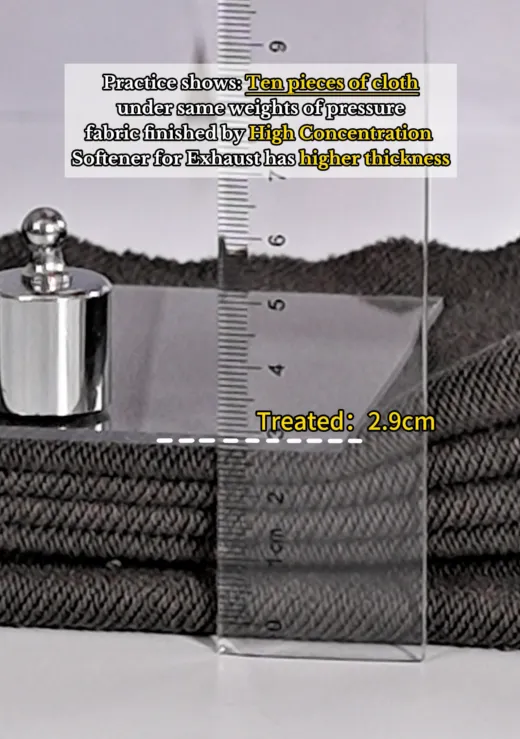

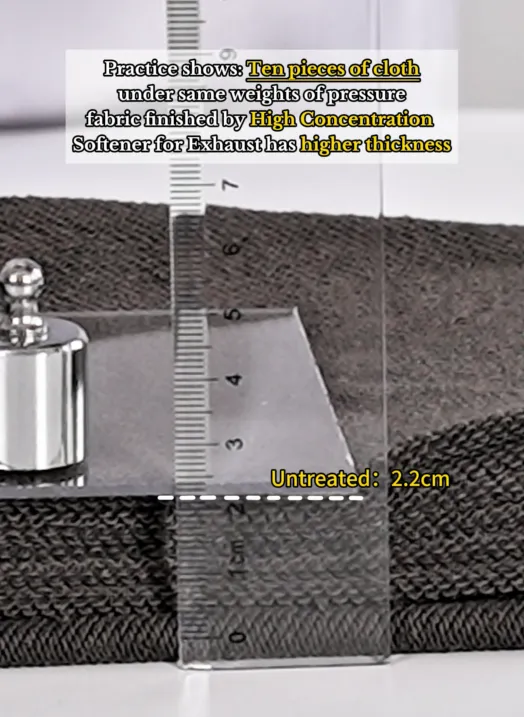

Makes Fabrics Softer, Smoother and Fluffier

Bath Softener 68002 is adopted advanced compounded technology to impart fabrics excellent handle:

- Soft and smooth: Improves the smoothness of cotton fabric surface.

- Fluffy and bulky: Improves deep-textured effect and handle of fabric surface.

- Buena hidrofilia: Keeps good moisture absorption.

- Low yellowing and low shade changing: Not interferes with the dyeing effect.

- Wide fiber compatibility: Suitable for cotton, CVC, T/C and R/C, etc.

Unlike conventional flakes or softening tablets, Bath Softener 68002 does not cause fabric stickiness or oily touch, making it suitable for high-grade towel fabrics, knitted fabrics, home textiles and sportswear.

Why to Choose Bath Softener?

The traditional softening process is usually inserted after dyeing, which adds process steps, increases cost and limits flexibility for rework. Fabric Bath Softener 68002 allows softening to be done directly in the dyeing bath, bringing significant advantages.

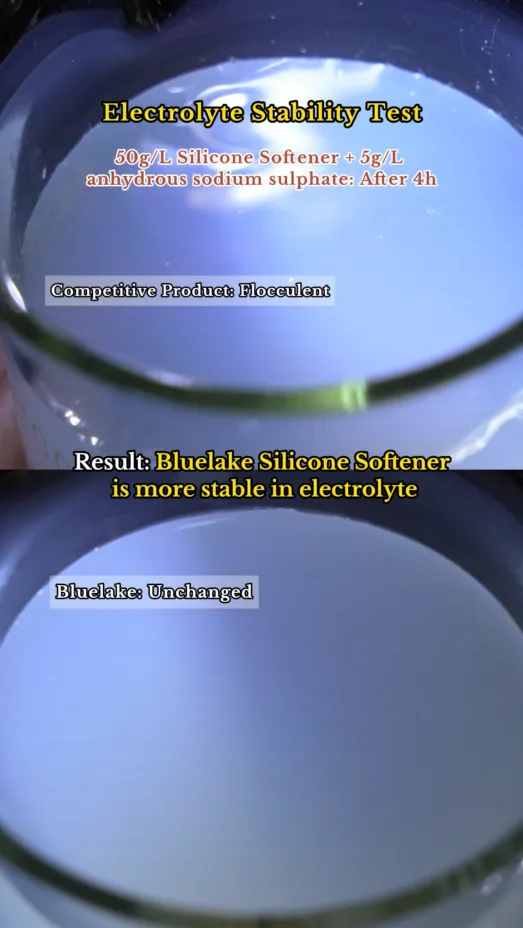

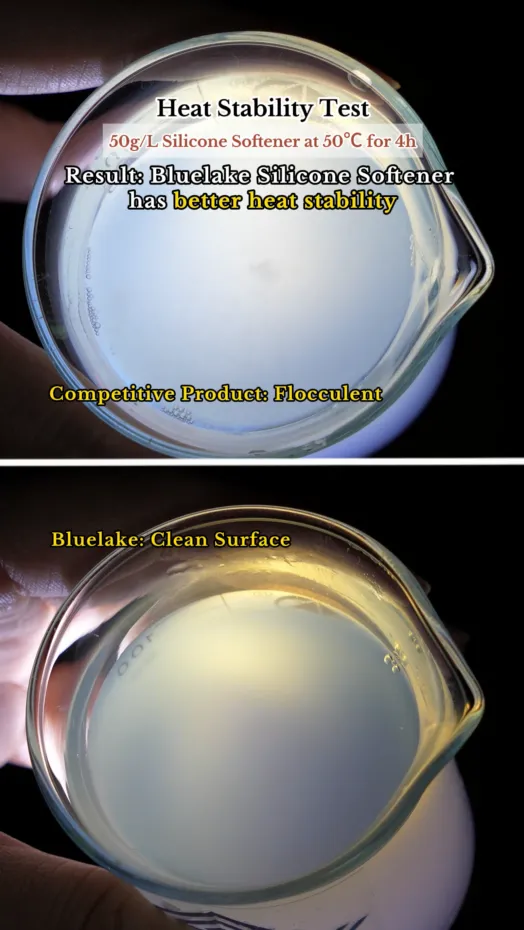

1. High stability in bath – Not afraid of high temperature, alkali or hard water

Fabric Bath Softener 68002 can keep stable in high temperature, strong electrolyte and alkali condition without delaminating, demulsifying or oil floating. Thus, it is very suitable in

- Reactive dyeing bath

- Soaping bath

- Salt or alkali condition

- High-shear pump circulation system

It ensures consistent hand feel on the entire batch and prevents uneven finishing.

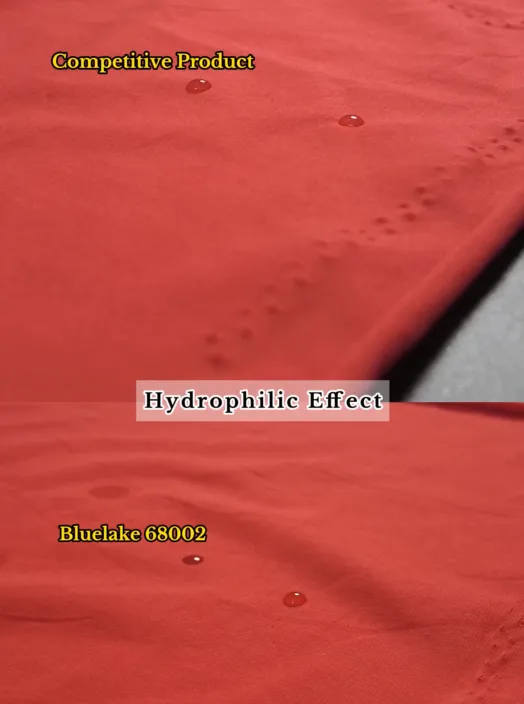

2. Hydrophilic softness – Soft without blocking water absorption

Different from the ordinary softener that will make fabrics “hydrophobic”, Fabric Bath Softener 68002 can form a hydrophilic soft layer that makes fabrics:

- Absorb water quickly

- Breathable for wearing

- Suitable for towel, sports fabric and underwear, etc.

3. Easier for mending – Modification dyeing is still possible

If color adjustment or rework is needed:

- The softener can be stripped off easily

- No influence on secondary dyeing

- No risk of shade variation

Very suitable for export orders and fabrics with strict color difference requirements.

4. High concentration and more cost-effective

Fabric Bath Softener 68002 is high-concentration product. It can be diluted by 1:9 and then used, which helps to save cost of transportation and storage. And it needs only very small dosage to achieve significantly soft and fluffy effect.

5. Wide Application

Fabric Bath Softener 68002 is especially suitable for following products:

- Cotton fabric, knitted fabric, towel fabric

- Blended fabrics, as CVC and T/C, etc

- Sports fabrics that need moisture absorption

- Looped fabric, fleece fabric and home textile fabric

- Soft finishing for high-grade cotton fabric

No matter in continuous padding process or exhaust process, Bath Softener 68002 can keep stable performance and achieve soft, even and consistent high-quality handle.

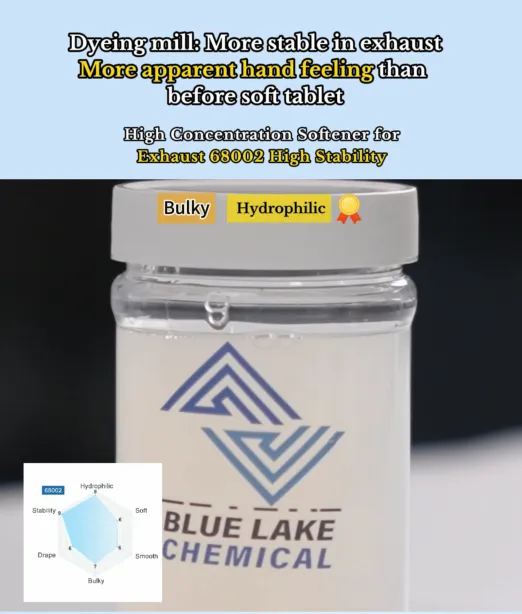

Recommend Product: 68002 High-Concentration Hydrophilic Bath Softener

Main features:

- Weak cationic softener. High stability

- Good hydrophilicity. Not influences moisture absorption

- Low yellowing. Low shade changing

- High stability: Resistant to high temperature, electrolyte and hard water. High shear resistance

- Suitable for using in exhaust and padding process both

- Can replace the traditional soft flake or ordinary bath softener

- A very small dosage can achieve excellent handle

Dosis de referencia:

- Exhaust process: 1.0~3.0% (o.w.f)

- Padding process: 10~30 g/L

Acerca de BLUELAKECHEM

BLUELAKECHEM specializes in researching and manufacturing auxiliares textilesincluyendo:

- Auxiliares de pretratamiento

- Auxiliares de tintura

- Auxiliares de acabado

- Functional finishing agent

We are committed to helping global dyeing and finishing enterprises reduce energy cost, improve production efficiency and achieve high-performance, eco-friendly fabrics.

Our products comply with OEKO-TEX®, ZDHC and REACH standards and are widely trusted by overseas dyeing mills and textile plants.

If you need to know more about product details or get sample, welcome to contacta con nosotros. We will provide you with professional technical support and solutions.