In textile dyeing and finishing production, pretreatment is often regarded as the previous preparatory process. But in the actual production, it plays a decisive role in the evenness of dyeing, color stability and total quality of fabric. For overseas dyeing mills, textile manufacturing enterprises and textile chemicals distributors, a clear understanding of the कपड़ा पूर्व उपचार process is an important prerequisite for achieving stable and repeatable production.

This article will have a systematical introduction to the textile pretreatment process, including main purpose, common procedures and basic control points.

What Is Textile Pretreatment Process

Textile pretreatment refers to the process of removing impurities and improving the wetting ability and liquid absorption of fabrics through a series of physical and chemical treating methods before dyeing or printing.

Different from dyeing or finishing, pretreatment does not directly determine the final appearance of fabric, but provides a clean, even and stable base fabric state for subsequent processes, thereby ensuring that dyes and finishing agents can function normally.

Main Purpose of Textile Pretreatment

Regardless of the type of fibers, the pretreatment process usually focuses on the following goals:

- Removes natural impurities and processing residues, such as wax, pectin, grease and sizing agent.

- Improves wetting performance of fabrics and permeability of working solution.

- Ensures the evenness of dyeing and batch stability during the dyeing process.

- Provides consistent fabric surface condition for subsequent dyeing and finishing.

Insufficient pretreatment will often cause dyeing defect, streaks or color differences between batches during the dyeing process.

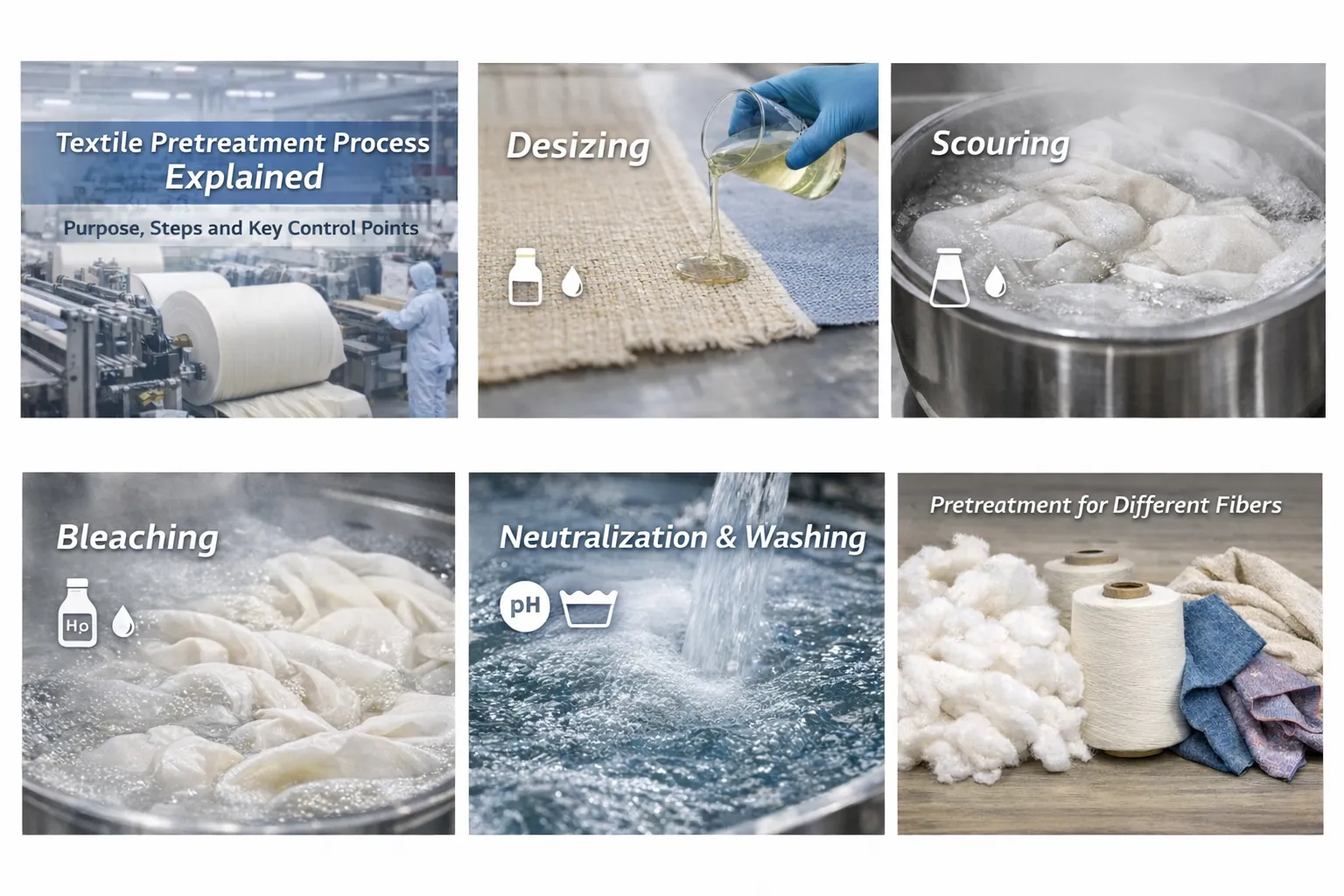

Common Textile Pretreatment Processes

1. Desizing

Desizing is mainly used in woven fabrics to remove the sizing from warp yarns.

- Common method: Enzyme desizing, alkali desizing or compound desizing.

- Key points: Removes the sizing thoroughly without damaging the fibers.

- Treating effect: Improves the moisture absorption of fabrics to make the surface cleaner.

2. Scouring

दस्त is mainly applied in cotton and other natural fibers to remove was, grease and non-fibrous substances.

- Traditional alkali scouring or biological enzyme scouring can be adopted.

- Obviously improves hydrophilicity and cleanliness.

3. Bleaching

When fabric needs higher whiteness or to be dyed light color, usually it needs bleaching.

- Commonly used system: Hydrogen peroxide bleaching

- Key controls parameter: Temperature, pH value and treating time.

- A reasonable bleaching stabilization system helps to prevent fiber damage or yellowing.

4. Neutralizing and water washing

After scouring or bleaching, there must have neutralizing and thorough water washing so as to remove residual chemicals and make the pH of fabric restore to the range suitable for dyeing.

The Pretreatment Characteristics of Different Fibers

- Cotton and natural fibers: Mainly removes natural impurities and improves moisture absorption.

- Synthetic fibers (such as polyester and nylon): Mainly removes spinning oil and surface contaminant.

- Blended fabrics: Needs to take into account the tolerance of different fibers. The process design is more comprehensive.

The Importance of Pretreatment to Dyeing Quality

The quality of pretreatment directly influences the permeability, evenness and color stability of dyes. A good pretreatment can decrease the risk of dyeing, improve the first-passyield and ensure the repeatability of production results.

BLUELAKECHEM के बारे में

ब्लूएलेकेम has been focusing on researching, developing and producing कपड़ा सहायक. We have been serving overseas dyeing mills, weaving mills and textile chemical distributors. Our company provides a product system covering the entire process of textile pretreatment, including wetting agent, desizing enzyme, डीग्रीजिंग एजेंट, emulsifying agent, पृथक्करण एजेंट, hydrogen peroxide stabilizer and low foaming soaping agent, etc.

In addition to supplying product, BLUELAKECHEM also provides customers with technical support from laboratory sample testing to optimization of on-site process formula, assisting factories in enhancing the stability of pretreatment, reducing energy consumption and risk of wastewater discharge. At the same time, our company product line also covers dyeing auxiliaries, functional finishing agents, silicone oil और सिलिकॉन सॉफ़्नर. We can provide customers with an integrated textile auxiliaries solution from pretreatment, dyeing to finishing.

If you need to get more detailed technology data, sample support or process suggestion, BLUELAKECHEM can provide targeted solutions and continuous technical support according to fabric types, equipment conditions and production goals.