Today, in the pursuit of energy conservation and efficiency improvement, the textile dyeing and finishing industry is constantly advancing through technological innovation. Among the highly anticipated technical progresses is Polyester Dyeing Carrier. It’s specially designed for medium- and light-colored polyester and polyester blends, and can achieve dyeing at normal pressure and low temperature, enhancing the quality and efficiency of dyeing. As a leading textile chemical manufacturer, ब्लूएलेकेम introduces Dyeing Carrier 22108, validated through extensive experimental data.

The Challenge of Traditional Polyester Dyeing

Generally, traditional polyester dyeing needs high temperatures above 130℃ to ensure the dye uptake and color fastness of disperse dyes. This dyeing method not only consumes a lot of energy, but also has higher requirements for equipment, especially obvious restrictions for dyeing mills using normal-pressure dyeing machines.

The Solution: Dyeing Carrier 22108 — Efficient Dyeing at 98–100°C

Dyeing Carrier 22108 contains various aromatic organic acid ester compounds (Content of effective elements≥85%). It is a high-concentration carrier with high cost performance. In the dyeing process, by expanding the polyester fibers, it can increase the penetration and dye uptake of dyes at a low temperature.

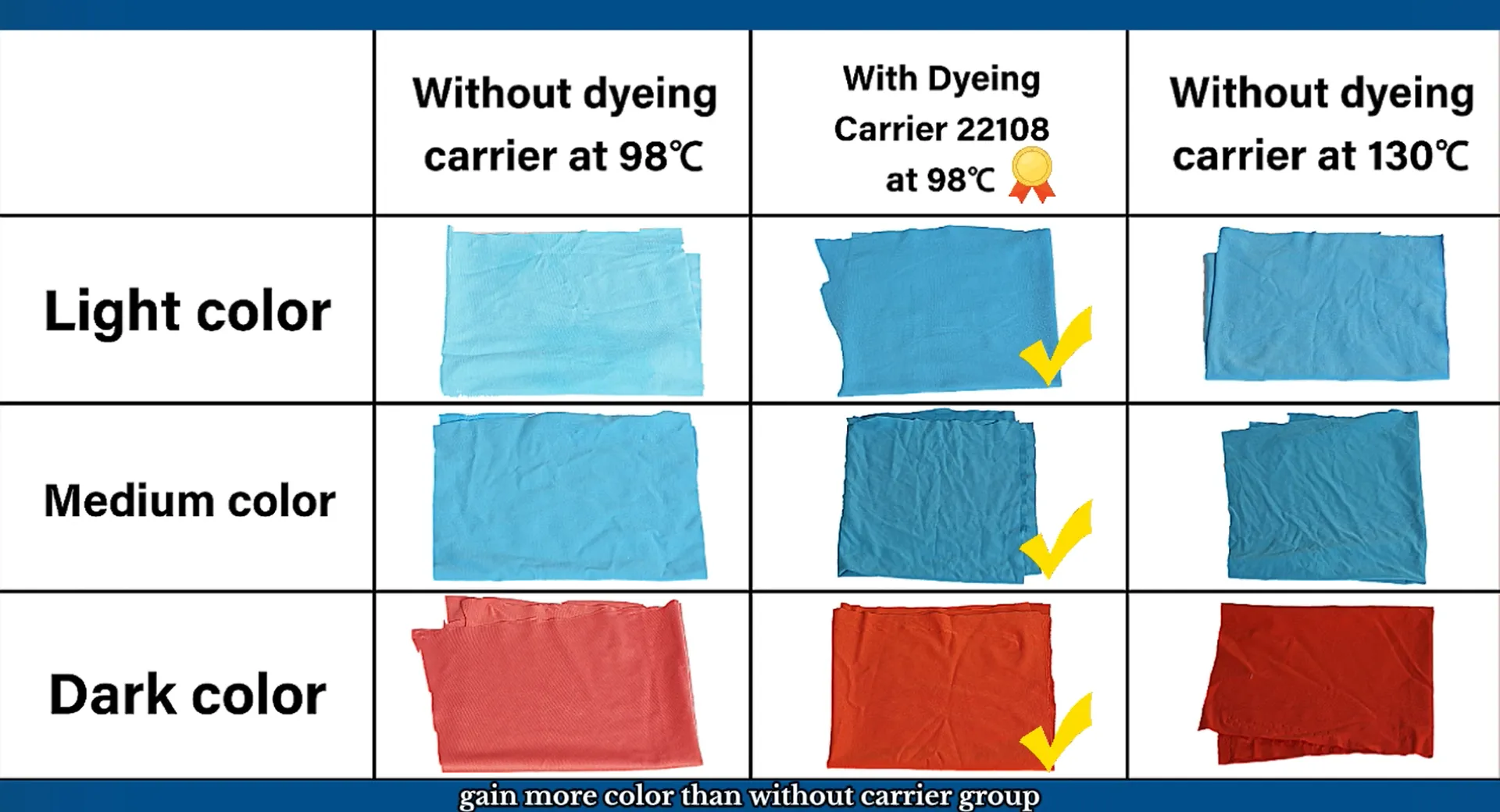

Experiment 1: Dyeing Efficiency at 98°C

Experiment Condition:

- Dyeing temperature: 98~100℃, keep for 45~60 minutes

- Dosage of carrier: For medium and light color: 1~3 g/L

- pH: 4.5~5.5

Experiment Result:

| Condition | Result |

|---|---|

| With carrier 22108 at 98°C | Deep, vibrant, even color |

| Without carrier | Dull, light color |

Under normal temperature of 98℃ and normal pressure, with carrier, light color and medium color can achieve the dyeing effect that is the same as under high temperature of 130℃ and high pressure. The color is more obvious than that without a carrier. But dyeing of dark colors is slightly worse than that dyed at high temperature and high pressure. For some dark colors, it cannot be achieved for the moment.

निष्कर्ष: Even with standard equipment, Dyeing Carrier 22108 delivers results close to high-temperature dyeing.

Takeaway: If your facility lacks high-temperature machines but wants to process polyester and blends, dyeing carrier 22108 is a cost-effective alternative.

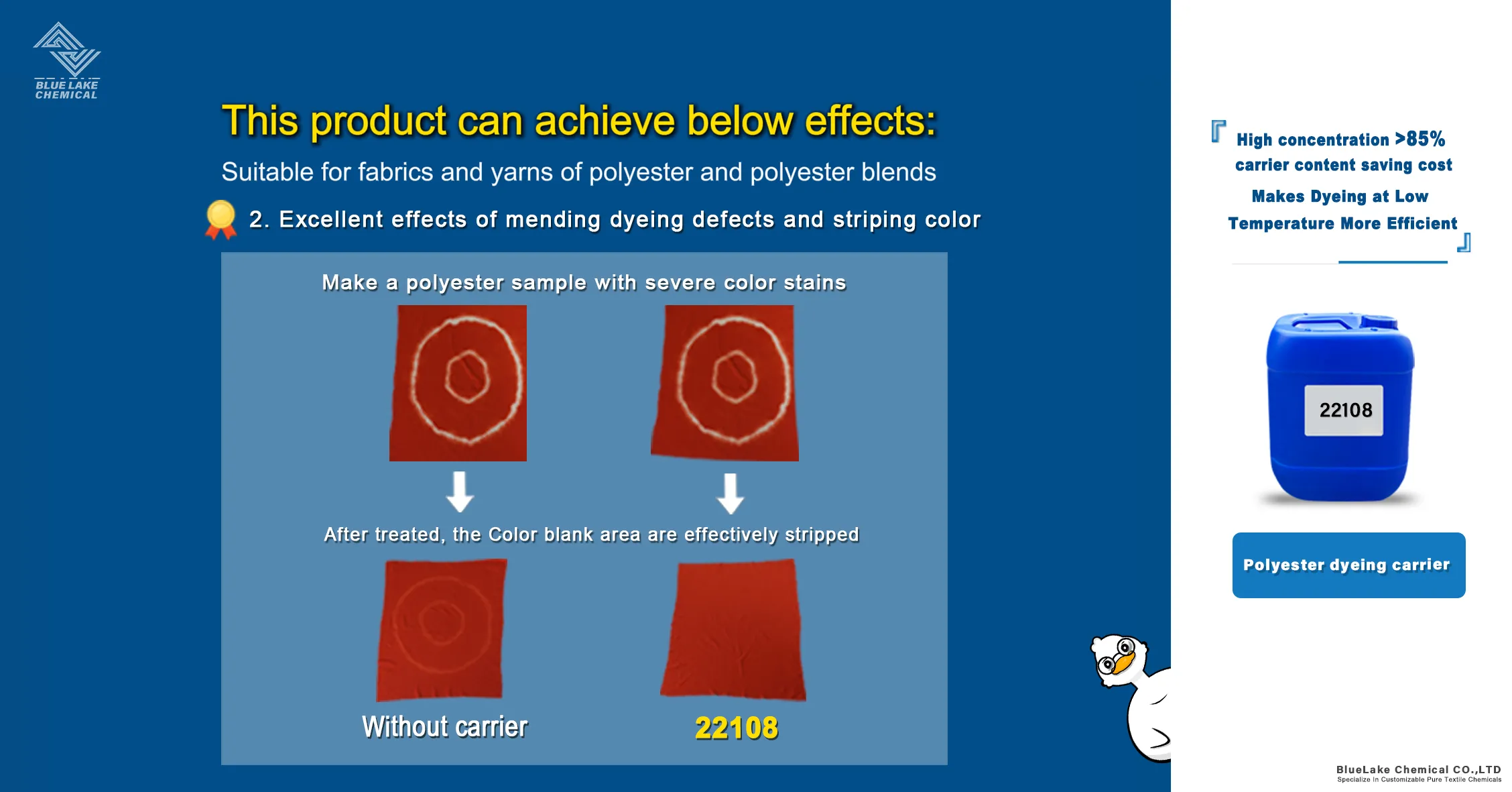

Experiment 2: Repairing Color Spots & Dyeing Defects

In the second experiment, it is to simulate more stubborn color spots than the common ones to see whether the dyeing defect can be solved or not. Firstly, prepare a polyester fabric with severe dyeing defects. Those stubborn color spots in daily life are usually not as serious as this one.

Experiment Result:

- The color spots and dyeing defects are weakened or even eliminated.

- The color of the mended area tends to be consistent with the original fabric. The overall consistency is greatly improved.

The Highlight of the Experiment:

It is worth emphasizing that it is not stripping color. Instead, it promotes the redistribution and re-dyeing of the dyes through a रंग वाहक, which makes the color transfer to the originally undyed area so as to achieve mending dyeing.

Why Choose 22108 Dyeing Carrier?

Proven by experiments, 22108 delivers consistent results even under normal pressure and low temperature. Designed to simplify polyester dyeing while enhancing color performance and operational flexibility.

Key Features and Application Benefits

| Highlight of Function | Actual Effect |

| Low temperature dyeing | A small dosage can achieve a good effect. Decreases the cost of auxiliary. |

| High content of active ingredients (≥85%) | A small dosage can achieve good effect. Decreases the cost of auxiliary. |

| Excellent dispersity | Makes dyes evenly diffuse in fibers more easily. Avoids color spots. |

| Good heat stability | No residual carrier spots or background pollution |

| Strong ability to mend dyeing defects | Can mend color spots and dyeing defects. |

| Lower requirements for dyeing equipment | Saves investment of equipment. Improves sustainability. |

Wide Range of Applications

- 100% Polyester fabrics and yarns (light to medium shades)

- Polyester/cotton and polyester/viscose fiber blended fabrics

- Small and mid-sized dye houses limited to normal-pressure cotton machines

Recommended Process Parameters

| Depth of color | Reference dosage | Temperature of dyeing | Time |

| Medium and light color | 1–3 g/L | 98~110℃ | 45~60 minutes |

A Smarter, Sustainable Polyester Dyeing Solution

With its low-temperature performance, high efficiency, mending ability, and equipment flexibility, Dyeing Carrier 22108 is becoming a go-to solution for overseas dyeing and finishing factories.

If you want to reduce the energy consumption of dyeing and increase dyeing quality, or need to solve dyeing defects, please consider applying for a trial to start the experience of the new-generation dyeing process.

Welcome to contact us to get a free test sample and technical support.

BLUELAKECHEM – Your Reliable Partner in Textile Auxiliaries