การเตรียมสิ่งทอเบื้องต้น is like laying the foundation for building a house. If greasy dirt, sizing agents and impurities are not thoroughly removed, there will easily appear dyeing defect, color spots and contamination in subsequent dyeing. However, in reality, the stubborn, greasy dirt on the fabric surface, the wide variety of auxiliaries and the strict environmental protection requirements make the pretreatment process often complex and costly. Is there a solution with “one agent and multiple effects” that makes the pretreatment more efficient and environmentally-friendly?

Pretreatment Challenges: Oil Stains, Complexity, and Cost

In the traditional process, generally, desizing, degreasing and scouring need various auxiliaries and steps:

- Stubborn, greasy dirt: It is difficult to remove silicone oil and heavy oil from the fabric surface of synthetic fibers and spandex fiber.

- Complicated process: Different fabrics need different formulas. It is complicated to control.

- High rework rate: If pretreatment is not thorough, it will cause uneven dyeing and increase rework.

- Pressure for environmental protection: Containing prohibited substances such as APEO has become difficult to meet international environmental protection laws and regulations.

These problems have caused many dyeing and finishing mills to bear high costs and high risks in the pretreatment process.

Dyeing Mill Pain Points: Rework, Management, Compliance

When visiting overseas markets, many dyeing mills generally reflected that:

- High re-work rate: Residues of pretreatment lead to uneven dyeing, increasing working hours and costs.

- Complicated management: Different batches and different fabrics need different auxiliaries. It is complicated to unify the preparation of auxiliaries.

- Environmental Compliance: Export orders require that it does not contain prohibited substances such as APEO, which makes it difficult to use traditional formulas.

These demands make the solution of “one agent with multiple effects, simplified process and environmental protection compliance” particularly urgent.

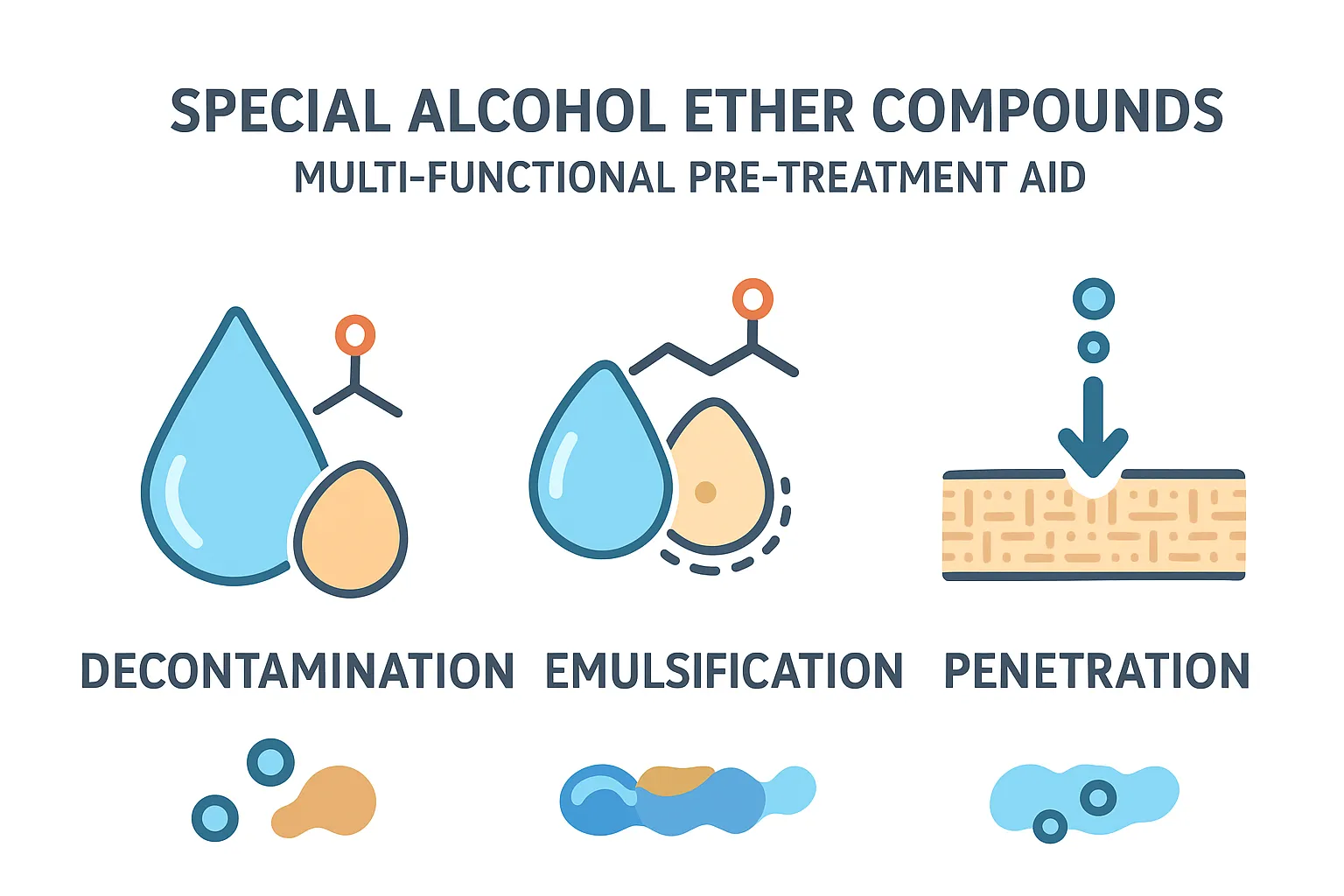

Special Alcohol-Ether Complex: Molecular Structure and Multi-effect Mechanism

The key to solving the problem lies in molecular design. One end of the molecule of the special alcohol-ether complex is lipophilic and the other is hydrophilic:

- Lipophilic end: Strongly emulsifies and removes greasy dirt and sizing from fabrics.

- Hydrophilic end: Promotes water molecules to penetrate rapidly into fibers and improves the scouring efficiency.

- Synergistic effect of compounding: Achieve “Three-in-one effect” of desizing, degreasing and wetting.

This mechanism breaks the traditional model of “multiple agents dividing the work”. Instead, just one agent can achieve cleanliness, wetting performance and fiber safety.

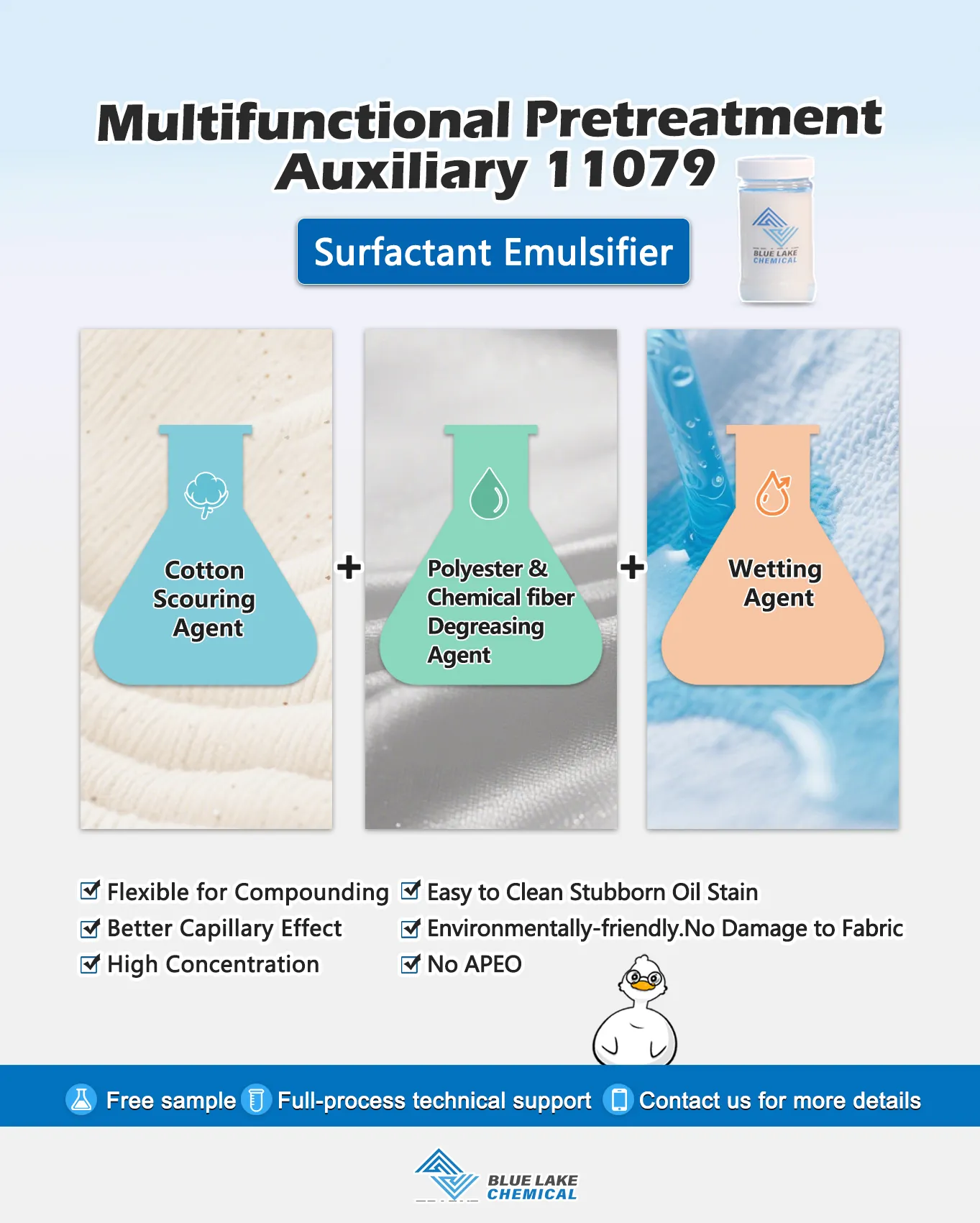

Multi-functional Textile Pretreatment Auxiliary: An Agent with Three Functions

The multi-functional textile pretreatment auxiliary researched and developed based on the above principle can help dyeing and finishing mills to solve the key pain points:

- Flexible compounding: Can be used to compound scouring agents for cotton and degreasing agents and wetting agents for polyester and other chemical fibers.

- Removes dirt efficiently due to its strong emulsifying ability. Thoroughly removes sizing, chemical fiber spinning oil, cotton wax, pectin and heavy oil.

- Anti-back-staining of dirt: Prevents greasy dirt or impurities from staining on the fabric. Can easily deal with fabrics of high whiteness.

- Multiple effects in one agent: General purpose for cotton, viscose fiber, Tencel, Modal, chemical fibers and their blends.

- Environmentally-friendly and safe: Contains no prohibited substances such as APEO, etc. Meets the environmental protection requirements of the European, American and Southeast Asian markets.

- Mild to fibers: Cleans effectively while protecting the fiber structure at the same time. Do not damage the fiber strength.

It is especially suitable for a dyeing mill that has several production lines. It can be applied to natural and synthetic fibers, as cotton, polyester and nylon, etc., and also blended elastic fabrics, as cotton/spandex and polyester/spandex, etc.

Recommended Solution:11079 Multi-functional Pretreatment Auxiliary

11079 Multi-functional Textile Pretreatment Auxiliary researched and developed by BLUELAKECHEM is especially for the pretreatment process, which integrates desizing, degreasing and improving wetting performance:

- Appearance: Colorless to light yellowing transparent liquid

- Ionicity: Nonionic

- pH (1% aqueous solution): 7.0±1.0

- Reference dosage: 1.0~3.0 g/L

- Process: Suitable for both the exhaust and padding processes both. Stable in high temperature and high alkali without delaminating.

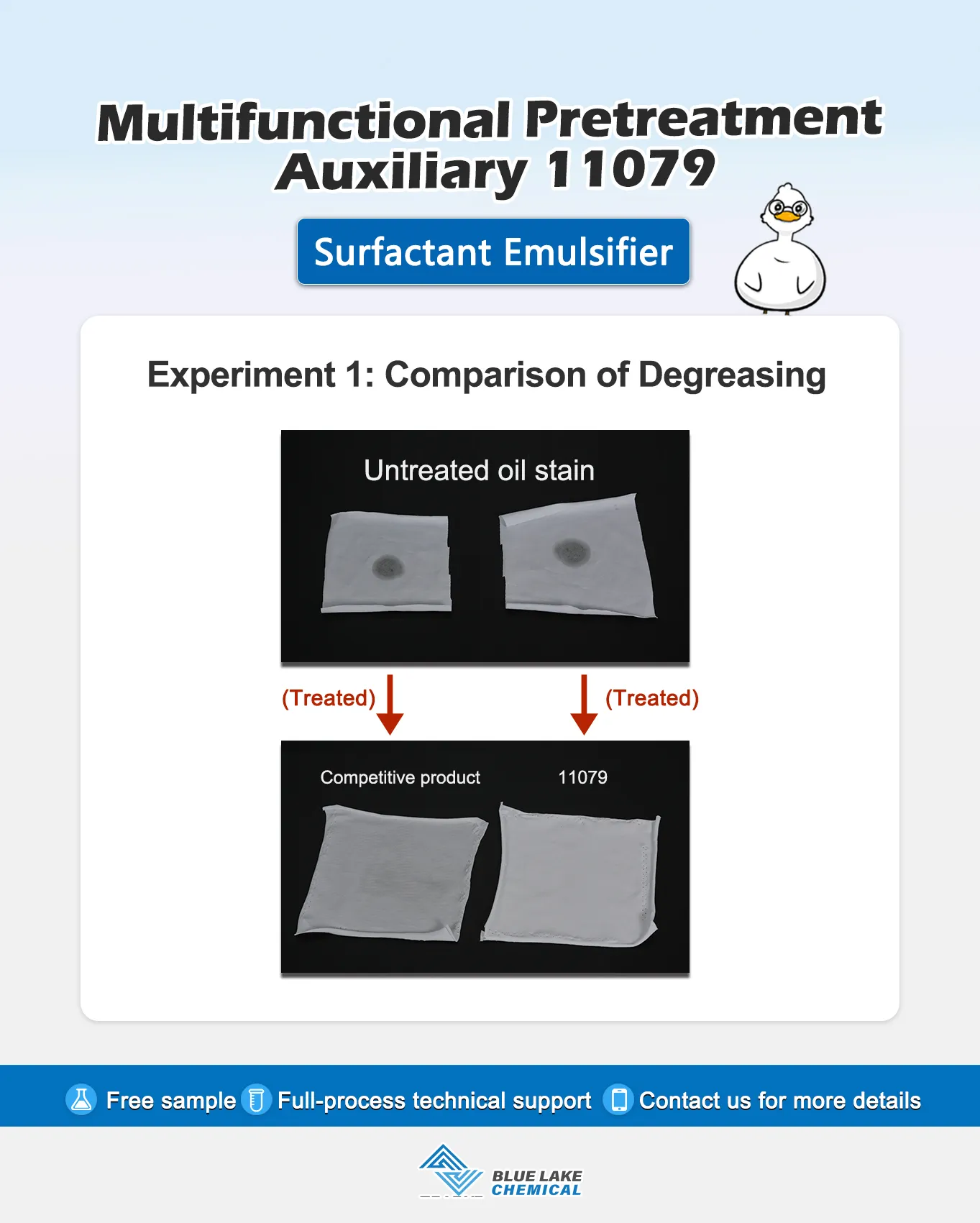

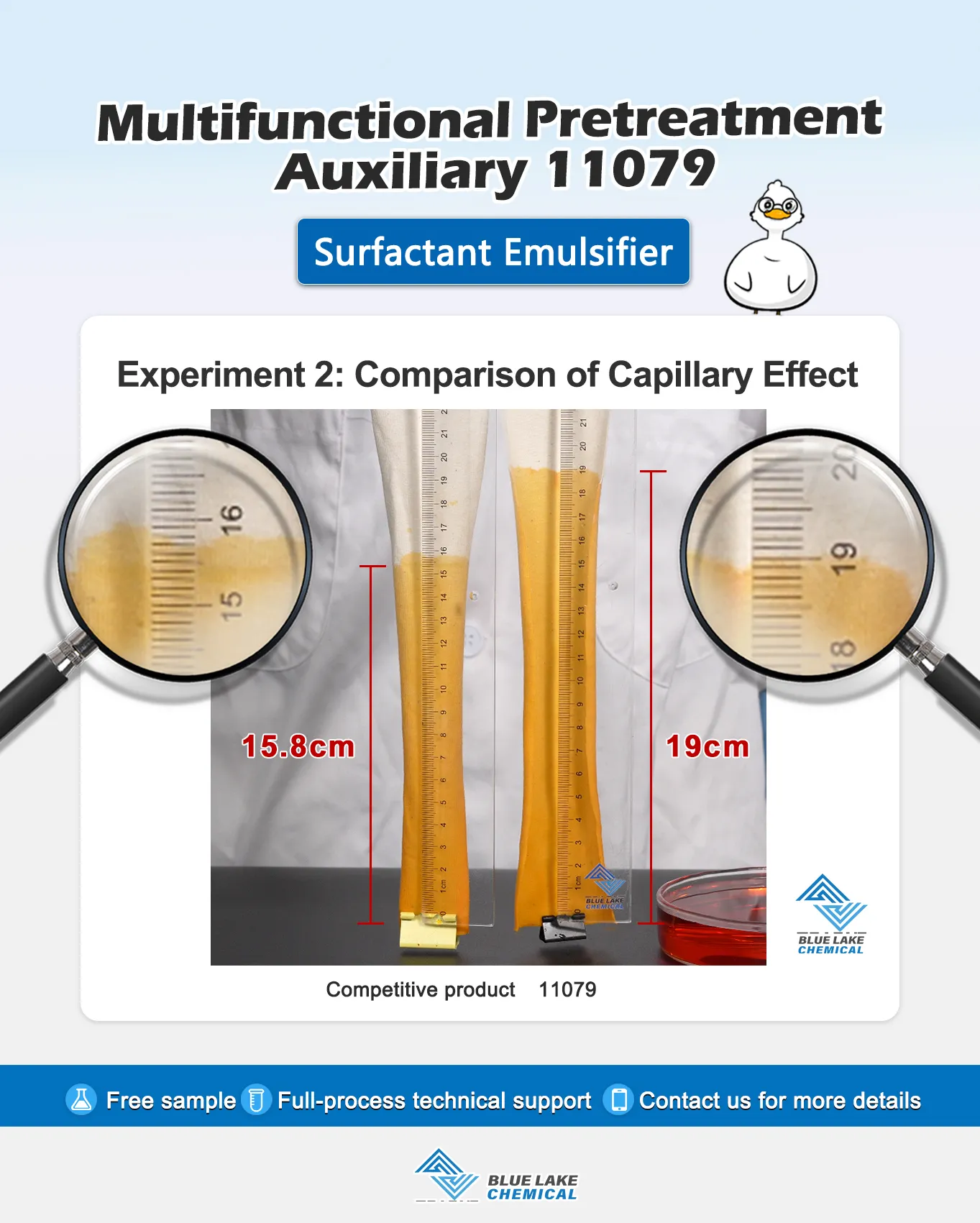

Comparison of Actual Measured Data and Effect: Better cleanliness and hydrophilicity

- Experiment of removing dirt: After treatment, the greasy dirt residue on the fabric is significantly reduced and dyeing evenness is improved.

- Experiment of capillary effect: The diffusion velocity of water drops is accelerated. Hydrophilicity is obviously strengthened. Subsequent dyeing is more thorough.

The experiment result shows that multi-functional textile pretreatment auxiliary can effectively solve the residue of greasy dirt and insufficient wetting in the traditional process. It can ensure the cleanliness and dyeing stability of fabric.

We sincerely invite you to ask for the 11079 Multi-functional Textile Pretreatment Auxiliary sample to verify the application effect in your production line.

เกี่ยวกับบลูเลคเคม

บลูเลคเคม is dedicated to providing high-performance, environmentally friendly auxiliaries to the global textile industry, covering pretreatment, dyeing, และ finishing. Our products are widely exported to Southeast Asia, the Middle East, Africa, and South America. We adhere to the principles of environmental friendliness, stability, and efficiency, helping customers improve production efficiency and end product quality. Please contact us to request samples of our 11079 multifunctional textile pretreatment auxiliaries and receive process support to verify their effectiveness on your production line.