Ön İşlem process provides an overall framework for textile processing. And what truly determine the effect stability is often the textile pretreatment auxiliaries used in each process. Reasonably choosing a pretreatment auxiliary can help to improve the process stability, reduce energy consumption and ensure the consistency of dyeing results.

This article will importantly introduce the types, mechanism of action and selection suggestions of pretreatment auxiliaries.

The Functions of Pretreatment Auxiliaries in Production

In modern textile pretreatment, auxiliary is mainly used to:

- Accelerate the wetting of fabric and the penetrating of working solution.

- Efficiently remove grease, was and residual sizing.

- Stabilize the bleaching system and protect the fibers.

- Control the influence of metal ions in water on process.

- Reduce foams and improve the adaptability of equipment.

If it is lack of suitable auxiliary, although the process design is reasonable, it is still difficult to achieve stable treating effect.

Common Types of Pretreatment Auxiliaries

1. Islatıcı madde

By decreasing the surface tension, it can make the working solution penetrate into fabric quickly and evenly.

Main Functions:

- Shortens processing time.

- Improves cleaning efficiency.

- Improves the evenness of pretreatment.

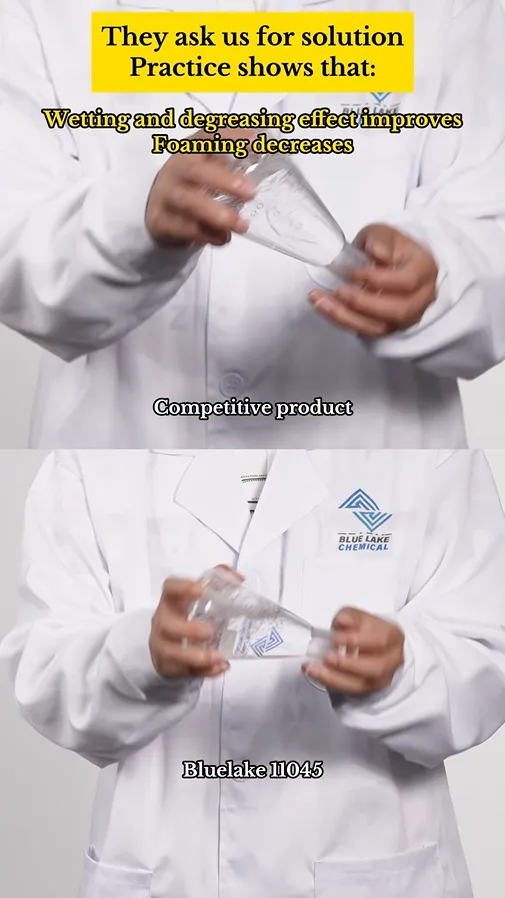

2. Yağ Alma Maddesi and Emulsifying Agent

It is used to remove the hydrophobic impurities, such as spinning oil and wax, etc. and stabilize and emulsify them, so as to prevent redeposition.

3. Desizing enzyme

It can decompose starch-based sizing under mild condition. It is suitable for environmentally-friendly desizing process.

Advantages:

- Reduces fiber damage.

- Decreases energy consumption.

- Improves handle of fabrics.

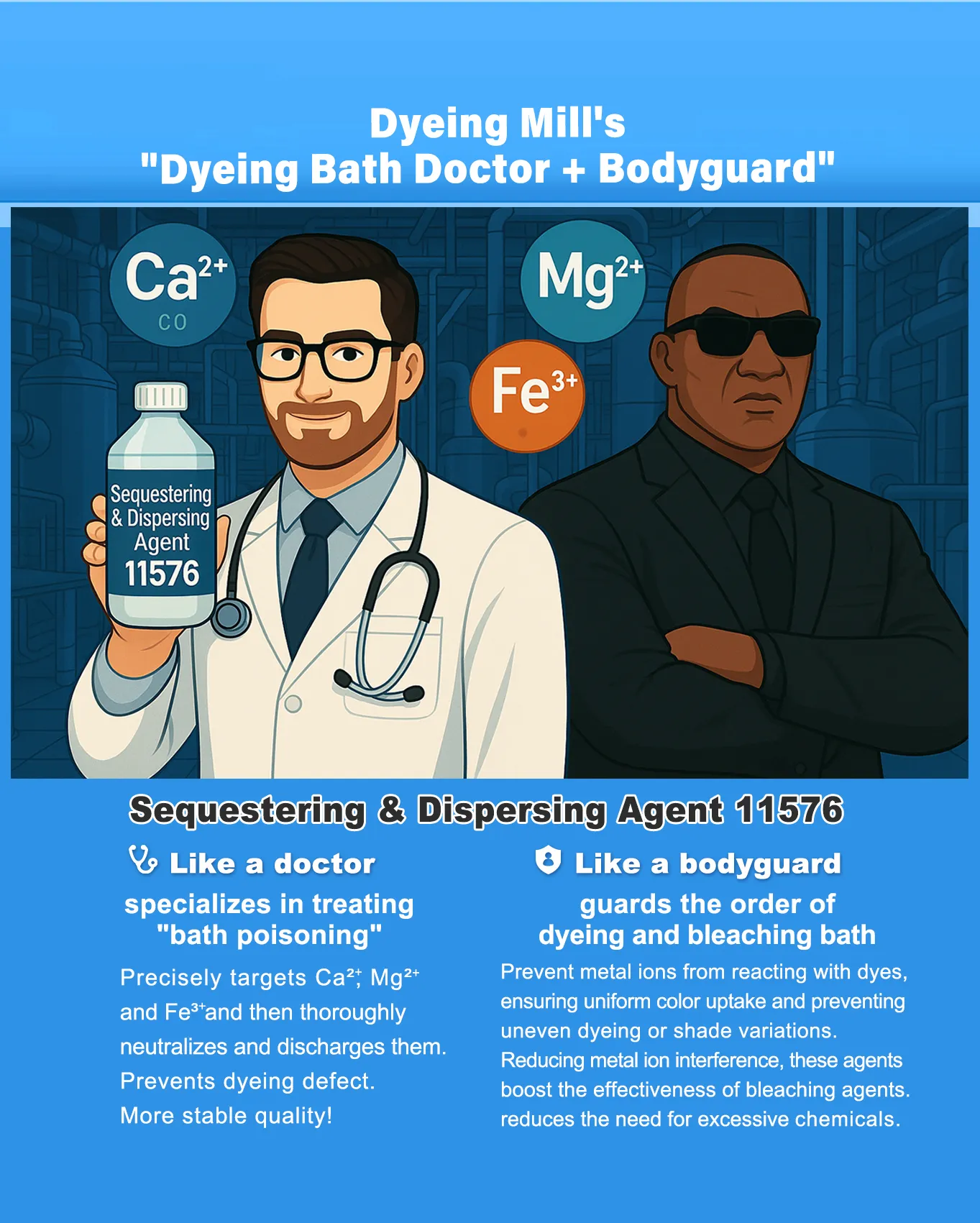

4. Sekestre edici ajan

It is used to complex metal ions such as calcium, magnesium and iron in water to prevent them interfering with bleaching or dyeing reactions.

5. Hydrogen peroxide stabilizer

It is used for hydrogen peroxide system to control the release rate of reactive oxygen.

Functions:

- Protects fiber structure.

- Improves evenness of bleaching.

- Decreases risk of yellowing.

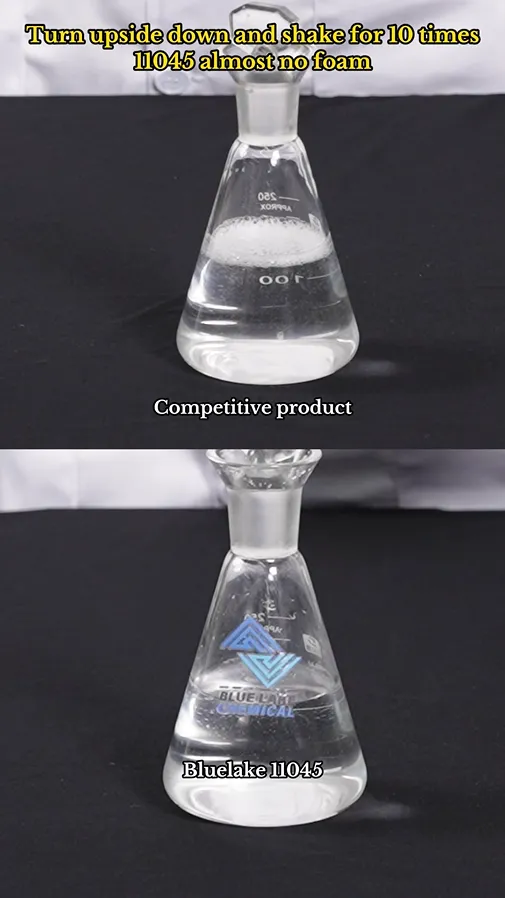

6. Low-foaming washing agent

It is suitable for continuous and high-speed equipment, which can ensure the washing effect as well as avoid foaming problem.

Suggestion for Choosing Pretreatment Auxiliaries

When choosing pretreatment auxiliaries, it needs to take the following factors into account:

- Fiber types and fabric structure.

- Equipment (intermittent or continuous).

- Water quality and hardness.

- The compatibility with subsequent dyeing and finishing processes.

- Requirements of environmental protection and regulation.

Selection based only on price often leads to higher hidden costs in subsequent production.

Achieve Process Optimization by Choosing Reasonable Auxiliary

Scientifically matched pretreatment auxiliaries can help dyeing mills to:

- Shorten processing time and decrease energy consumption.

- Reduce dyeing defect or rework.

- Improve consistency between batches.

- Support long-time stable production.

Therefore, choosing pretreatment auxiliaries is not only a technical issue but also an important link in cost control and quality management.

BLUELAKECHEM Hakkında

BLUELAKECHEM has been focusing on researching, developing and manufacturing teksti̇l yardimcilari. In the field of teksti̇l ön i̇şlemleri̇, we can provide a complete product system, including ıslatıcı madde, desizing agent, yağ çözücü madde, sekestre edici ajan, hydrogen peroxide stabilizer and low-foaming soaping agent, which are suitable for different fibers and processing conditions.

In addition to pretreatment products, BLUELAKECHEM’s product line also covers BOYAMA process, functional bitirme, silikon yağı and soft finishing series, which can support the whole process requirement from pretreatment to finishing. By combining practical application experience with technical services, we are committed to providing stable and reliable textile auxiliaries solutions for overseas dyeing mills and textile enterprises.