Silicone-Based Softener for Cotton – Smooth Hand Feel and Enhanced Finishing Performance

Cotton Softening & Smoothing Silicone oil 72108 is an innovative textile softener that provides excellent softness and smooth hand feel to most fabrics. Based on a novel linear block copolymer platform, it is copolymerized from polysiloxane, polyether, and polyamine. The product can uniformly penetrate into the interior of fibers and act on each individual fiber, thereby enhancing the overall finishing performance of the fabric.Oeko-Tex Standard 100 compliant. Contact us for free samples or expert guidance on formulas!

Model No. 72108

To'qimachilik kimyosi ishlab chiqaruvchisidan

Textile Chemicals Description

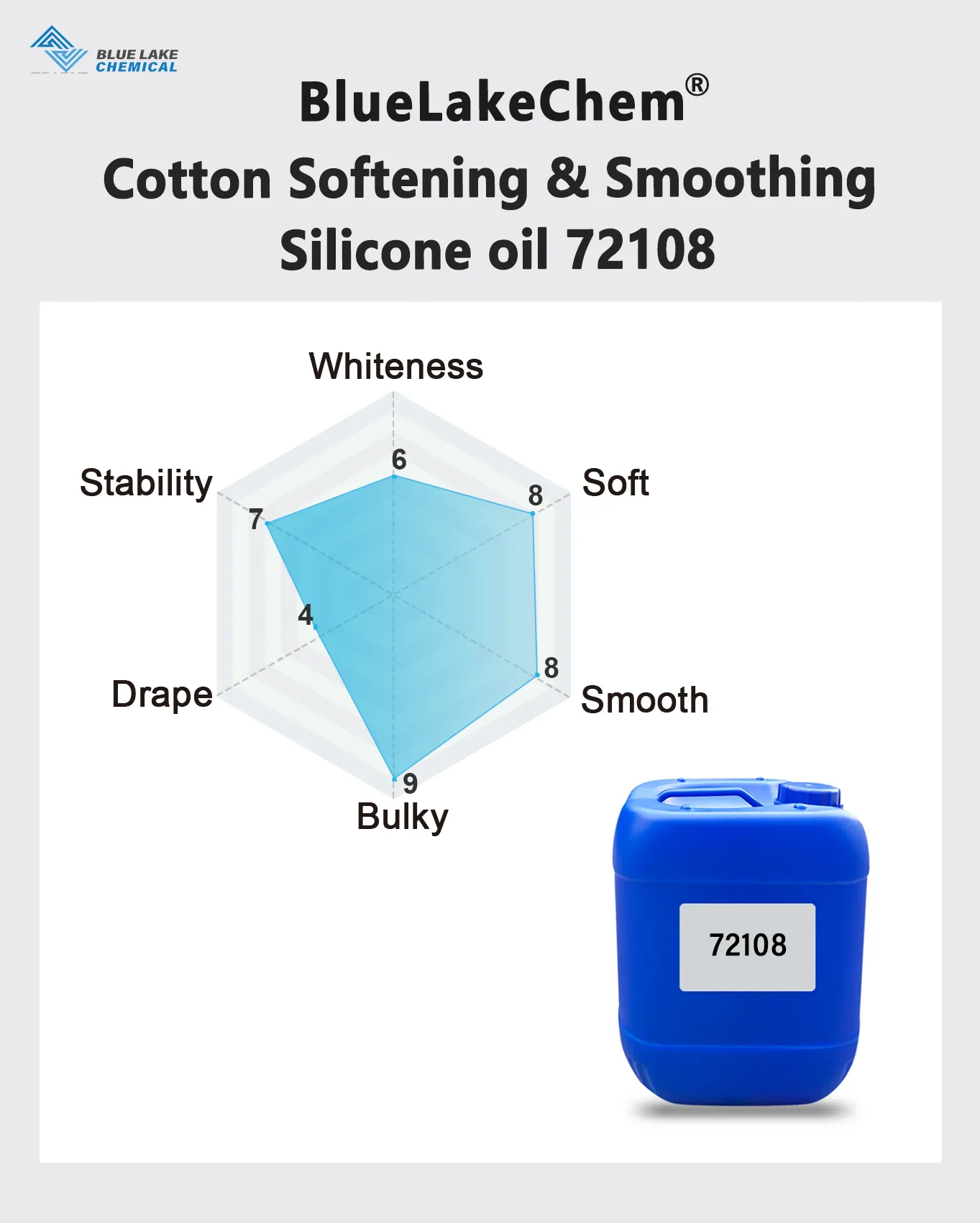

Cotton Softening & Smoothing Silicone oil Features

Silky Softness for Cotton Utilizing

linear block copolymer technology to impart a delicate, smooth, and supple hand-feel to cotton fabrics.

Cost Optimization Recommended dilution

1 ton of silicone concentrate to approximately 3.5 tons of finished emulsion, helping to optimize integrated freight and warehousing costs.

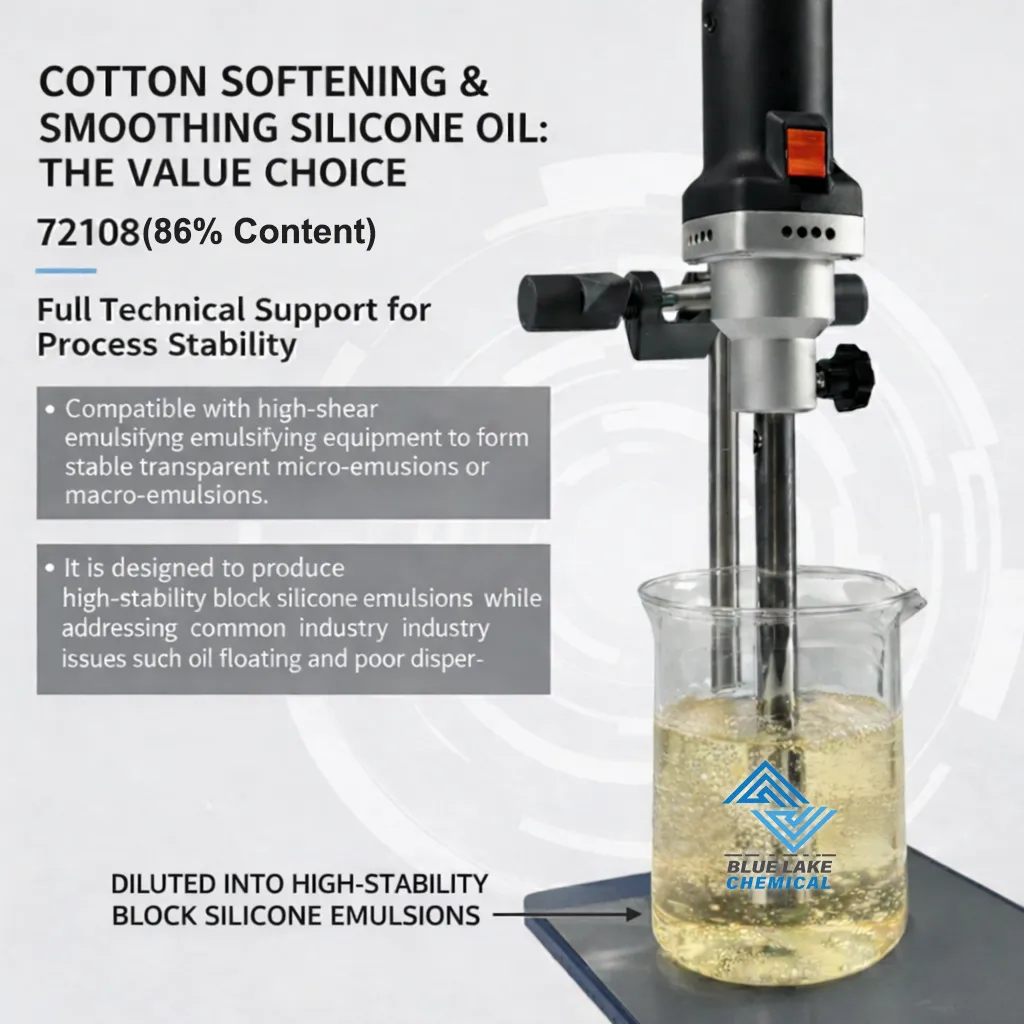

Technical Guidance & Processing Stability Full

dilution support for reliable operation and superior stability. Compatible with high-shear emulsifying equipment to form stable transparent micro-emulsions or macro-emulsions; designed to produce high-stability block silicone emulsions while addressing traditional issues such as oil floating and poor dispersibility.

Eco-friendly & Compliant

SVHC & Banned Chemicals Free | OEKO-TEX® 100 & ZDHC Compliant. Supporting high-end export growth.

Cotton Softening & Smoothing Silicone oil Instruction

72108 is a high-concentration, semi-self-emulsifying block copolymer raw oil, which cannot be directly applied to fibers or fabrics. Therefore, it should be emulsified before textile processing. It can be easily emulsified using conventional equipment and standard processes.

1) Emulsification Formula (Recommended)

| Component | Dosage (parts) | Remarks |

|---|---|---|

| CX-72108 | 100 | — |

| Emulsifier | 5 | Nonionic surfactant TO-5 (BASF recommended) |

| Glacial acetic acid + Water 1 | 1 + 30 | Dissolve 1 part glacial acetic acid in 50 parts deionized water |

| Water 2 | 214 | — |

| Total | 350 | — |

2) Emulsification Process

Stir 72108 and the emulsifier until uniform before use:

- Add 72108 and emulsifier into a mixer and stir thoroughly for 10 minutes until completely homogeneous;

- Slowly add the acetic acid + water 1 mixture and continue stirring for 10 minutes until uniform;

- Add approximately 1/5 of Water 2, stir for 5 minutes;

- Add another 1/5 of Water 2, stir for 5 minutes;

- Add the remaining Water 2, stir for 5 minutes;

- Allow to stand for defoaming, filter and discharge;

- Check the pH of the prepared solution (pH = 4.0–6.0). A clear micro-emulsion should be obtained.

3) Softening Application Process

Padding method (recommended)

- Dosage:

- Light-weight fabrics: 20–40 g/L

- Heavy-weight fabrics: 40–60 g/L

- Working bath pH: 6.0–7.0 (optimal range)

- Setting conditions:

- One dip–one nip (pickup 70–90%)

- 160–170°C for 60–90 seconds

Exhaust (immersion) method

- Dosage: 1.0–3.0% (o.w.f.)

- Liquor ratio: 1:20

- Jarayon:

- 40–50°C for 10–20 min,

- Hydro-extraction,

- Drying at 100–120°C.

Cotton Softening & Smoothing Silicone oil Properties

| Characteristics / Properties | Specification / Value |

| Main Composition | Linear multi-block polysiloxane copolymer |

| Appearance (visual) | Colorless to light yellow transparent liquid |

| pH value (at room temperature, test paper method) | 6.0~8.0 |

| Viscosity (25°C, mPa·s) | 500~1000 |

| Ionic nature | Kuchsiz katyonik |