In cotton yarn manufacturing, natural and artificial impurities in raw cotton can severely impact dyeing and finishing performance. Caustic soda (sodium hydroxide, NaOH) plays a vital role in the boiling and scouring stage of pretreatment, effectively removing impurities, improving dyeing ability, and boosting processing efficiency.

This article explains the key functions of caustic soda in cotton yarn pretreatment and recommends BLUELAKECHEM 11017 Alkali-resistant Degreasing & Wetting Agent, to improve the pretreatment effect.

Impurity Challenges in the Pretreatment of Cotton Yarns

Untreated raw cotton contains a large amount of non-cellulose components. If these components are not removed, they will cause the following problems during the dyeing and finishing process:

- Residual cottonseed hulls: Residues from the cotton ginning process adhere to the yarns.

- Natural wax and pectin: Adhere to the surface of cotton fiber, decreasing hydrophilicity.

- Protein and mineral components: Interfere with the chemical reactions during the dyeing process.

- Residues of sizing agents, Such as starch, PVA, and CMC etc., added in the weaving process, need to be removed before the dyeing process.

If these impurities are not completely removed, it will lead to the following dyeing and finishing defects:

- Uneven dyeing is a dyeing defect.

- Fixing the rate of dye decrease.

- Finished products have poor brightness and a rough handle.

- There is secondary pollution in the finishing process.

Role of Caustic Soda in Boiling & Scouring

As a strong alkali, caustic soda is widely used in the boiling and scouring process in the pretreatment of textiles. It has the following main functions:

1. Efficiently removes wax and pectin

Caustic soda can have saponification with the natural wax on the surface of fibers to convert hydrophobic substances into water-soluble soaps, thereby imparting cotton yarns good hydrophilicity and laying a foundation for even dyeing.

2. Change structure

For cotton fabrics or yarns containing starchy, PVA or CMC sizing agents, caustic soda can destroy their molecular structure, promote their dissolution and removal, and ensure the consistency of subsequent dyeing and finishing.

3. Softens and removes the cottonseed hulls and organic impurities

Caustic soda can penetrate into the interior of fibers to soften and disperse impurities such as embedded cottonseed hulls, so as to improve cleaning efficiency and reduce physical residues.

4. Promotes swelling of fibers and enhances liquid absorption

During the alkali solution treatment process, cotton fibers expand, the fiber surface area increases and porosity rises, significantly enhancing their absorption capacity for water and dyes, which is conducive to achieving a deep and even dyeing effect.

Typical Process Parameter of Caustic Soda

| Technological Parameter | Recommended range |

| Dosage of caustic soda | 4~10 g/L (Specific dosage is according to the condition of yarns and impurities.) |

| Temperature | 95~100°C |

| Time of processing | 30~60 minutes |

| Wetting agent (optional) | For enhancing wetting performance and improving treating effect |

टिप्पणी: Specific parameters should be adjusted and optimized according to the type, structure, and dyeing requirements of the cotton yarn.

Suggestions on Environmental Protection and Wastewater Treatment

The wastewater generated during the caustic soda treatment process usually has high alkalinity and organic loading. Enterprises need to establish effective neutralization and biochemical treatment systems to ensure that emissions meet standards. At present, many dyeing mills are gradually using biodegradable auxiliaries together with caustic soda to reduce the environmental burden and enhance the green sustainability of the process.

Boosting Caustic Soda Efficiency with BLUELAKECHEM 11017 Alkali-resistant Degreasing & Wetting Agent

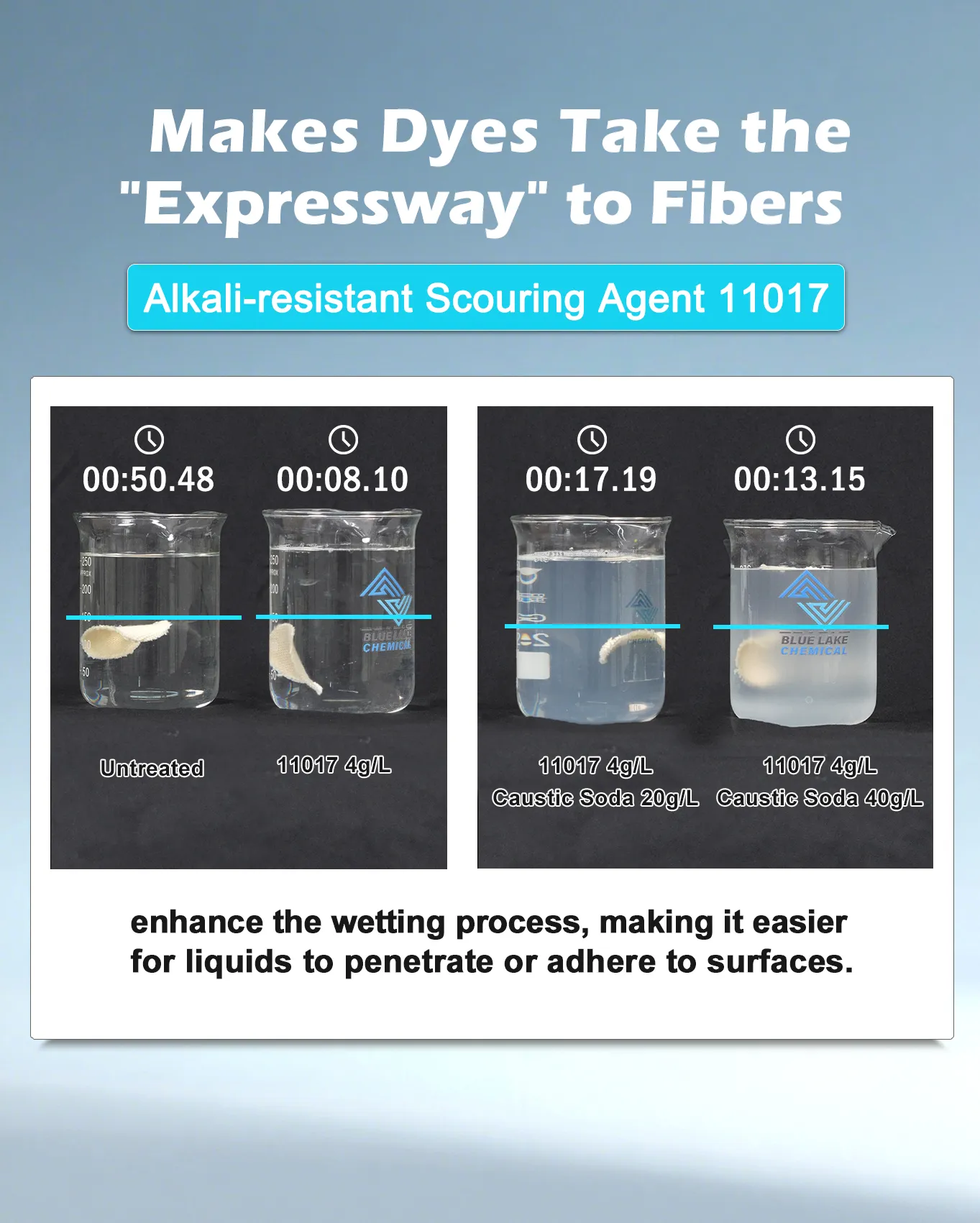

In order to further improve the cleaning effect of caustic soda boiling and scouring, it is recommended to use it together with BLUELAKECHEM 11017 Alkali-resistant Degreasing & Wetting Agent. This product is compounded by multiple surfactants, which have triple functions of degreasing, removing waxes and wetting. It is especially suitable for the desizing, boiling and scouring and bleaching process for cotton and cotton blends.

Key features:

- Improves the capillary effect and wetting performance of the fabric surface.

- Reduces waste of dyes.

- Improves printing effect.

- High stability. Good compatibility.

- Low foaming. Easy to wash. Saves water.

- Strong alkali resistance. Keeps stable in 100g/L alkalinity.

- No APEO. Environmentally-friendly.

Recommended Usage:

- Batch method: Dosage: 0.5~1.5 g/L, use with alkaline agent (such as sodium carbonate), 85℃×

30~50 minutes - Continuous method: Dosage: 2.0~5.0 g/L, suitable for open-width degreasing and desizing washing equipment.

By using 11017 degreasing agent with caustic soda, the dyeing mill can obviously improve the effect of removing impurities for cotton, shorten the time of processing, and improve dyeing consistency. It helps to establish a high-efficiency and environmentally friendly pretreatment process for cotton yarns.

BLUELAKECHEM के बारे में

ब्लूएलेकेम is focusing on providing high-performance and environmentally-friendly textile auxiliaries solutions. Our products include डीग्रीजिंग एजेंट, sequestering and dispersing agent, wetting agent और समतलीकरण एजेंट, etc., which are widely applied in pretreatment, dyeing and finishing processes for fibers.

If you have more demands for पूर्व उपचार सहायक, please feel free to contact us. We will provide you with customized technical support and product suggestions.