Low Temperature Soaping Powder for the Soap Boiling after Fabric Printing and Dyeing

Low Temperature Soaping Powder 22140 is mainly composed of polycarboxylate compounds. By chemical action of soaping agents and dyes, can elute the dyes on the cloth, which are not bonded to the fiber. Also, through the strong dispersing effect of the soaping agent, it can prevent the re-adhesion of dyes that are eluted. It can be applied in the low-temperature soaping and boiling process after dyeing and printing for fabrics of cellulose fibers, such as cotton, viscose fiber, flax, and cellulose fiber blends, etc. and is compliant with Oeko-Tex Standard 100. Contact us for free samples or expert guidance on formulas!

Model No. 22140

From Textile Chemicals Manufacturer

Textile Chemicals Description

Low Temperature Soaping Powder Features:

Eco-friendly and pollution-free: Contains no phosphorus or APEO, etc. Fits environmental protection requirements.

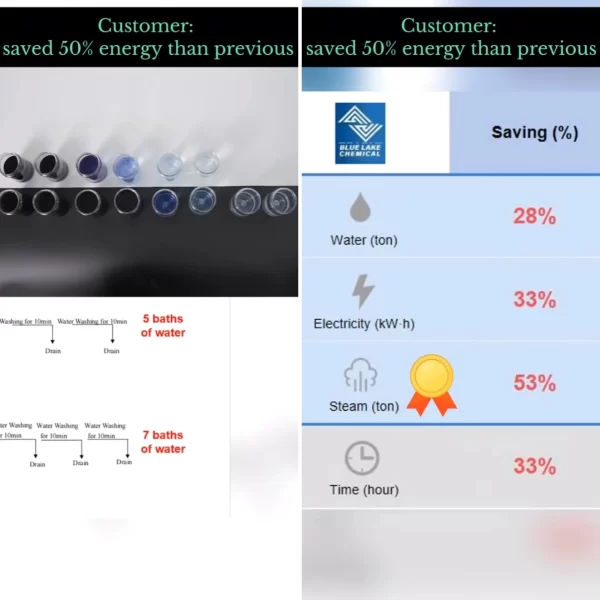

Low temperature and high efficiency: suitable for low-temperature soaping and soap boiling processes, saving energy and time.

Excellent function of dispersing and detergent washing: effectively strips off unfixed dyes and improves color fastness.

Excellent anti-staining property: Prevents tarnishing and improves printing effect.

No effect on color shade: Almost no effect on color shade, can increase the brightness of fabrics and enhance the quality of printing and dyeing.

Low Temperature Soaping Powder Properties:

| Appearance: | White powder |

| Ionicity: | Nonionic |

| pH value: | 12.0±1.0 (1% aqueous solution) |

| Solubility: | Soluble in water |

Low Temperature Soaping Powder Instruction:

Reference dosage:

Light color: 0.3 g/L

Medium color: 0.5 g/L

Dark color: 1 g/L

Reference process:

60~70℃×20~30 min, then drain → Water washing → Pickling (0.2 g/L acetic acid), then drain→ Fixing and softening