Nylon Hydrophilic Finishing Agent, Boost Washability & Surface Wettability

Hydrophilic Finishing Agent 44507 is mainly composed of polyurethane-modified polyether. It can undergo a cross-linking reaction with nylon fiber at high temperatures, chemically modifying the nylon surface to enhance the hydrophilic properties of nylon fabrics. It can be applied in the hydrophilic finishing process for fabrics of nylon and nylon blends. and is compliant with Oeko-Tex Standard 100. Contact us for free samples or expert guidance on formulas!

Model No.44507

From Textile Chemicals Manufacturer

Textile Chemicals Description

Hydrophilic Finishing Agent Features:

Eco-Friendly: Free from APEO, formaldehyde, and heavy metals; meets Oeko-Tex Standard 100.

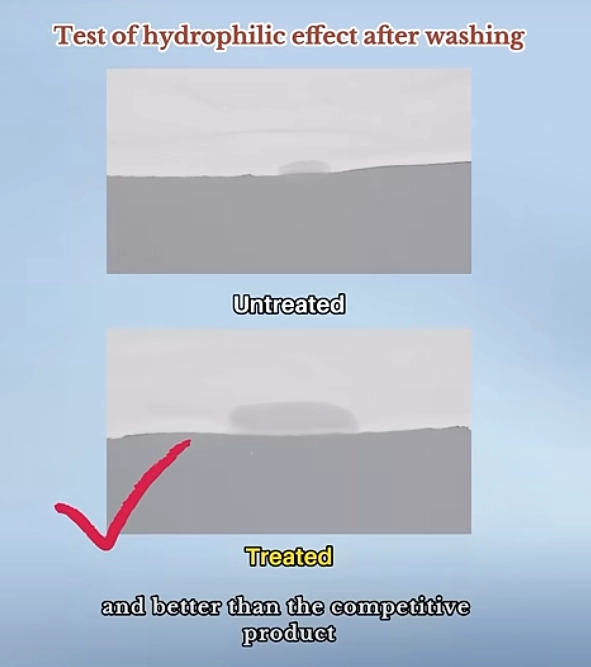

Superior Hydrophilicity: Significantly improves the moisture absorption and quick-dry performance of nylon and nylon-blend fabrics.

Durable Washability: Provides excellent resistance to repeated washing cycles without losing hydrophilic effect.

Stable Shade Retention: Low impact on fabric color, maintains original shade after finishing.

Soft Hand Feel Compatible: Does not affect the softness or feel when used with hydrophilic silicone oil.

Easy Application: Can be applied in the same bath with hydrophilic softeners or silicone oils in setting machines, streamlining the finishing process.

Hydrophilic Finishing Agent Properties:

| Appearance: | Light yellow to light brown liquid |

| Ionicity: | Weak cationic |

| pH value: | 4.0±1.0 (1% aqueous solution) |

| Solubility: | Soluble in water |

Hydrophilic Finishing Agent Instruction:

Padding process:

Reference dosage of 44507: 20~40 g/L

Reference dosage of Hydrophilic Silicone Oil: 10~20 g/L

Dipping and padding (Pickup: 70~100%) → Drying and setting (130~160℃)