Low Foaming Nonionic Wetting Agent in Textile for Cotton Polyester Fabric

High concentration and low foaming wetting agent, a small dosage can have a good wetting effect on each textile process without foaming, even helps to inhibit the foaming of other chemicals, and can be used as a high-efficiency wetting agent in the printing and dyeing process.

Model No. 11026

From Textile Chemicals Manufacturer

Textile Chemicals Description

Features of Wetting Agent in Textile:

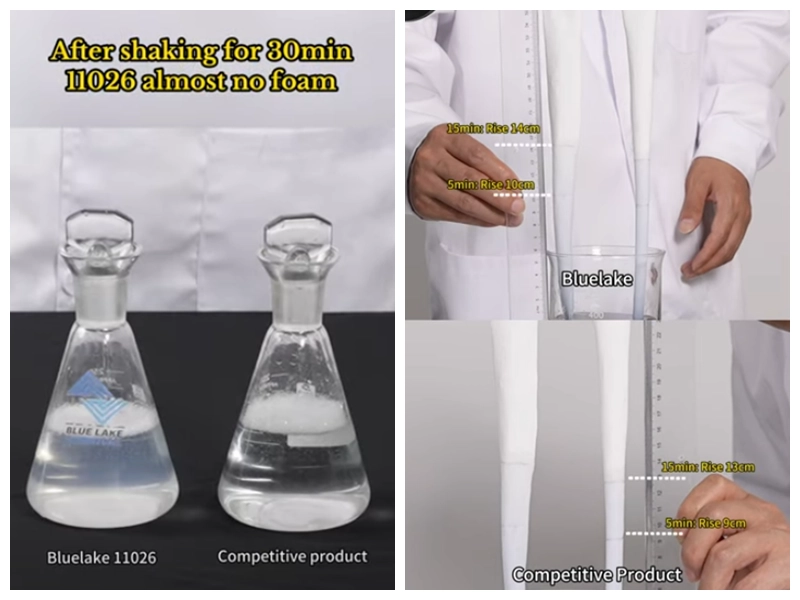

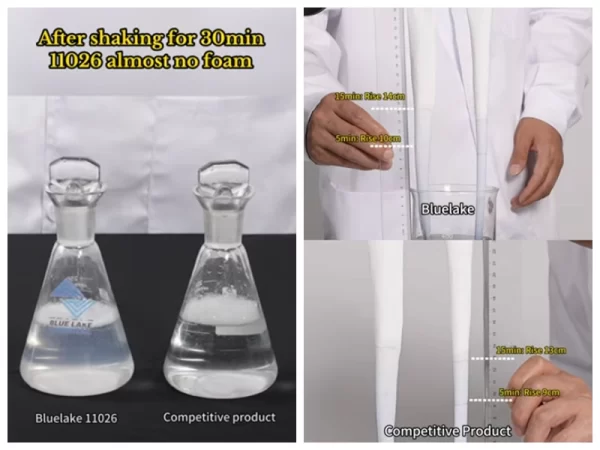

High Concentration, Low Foaming: Only a very small dosage is required to effectively penetrate various textile processes, ensuring optimal performance with low foam generation.

Rapid penetration and strong wetting: Quickly penetrates between fibers for deep, uniform treatment.

Enhanced dyeing uniformity: Suitable for printing and dyeing processes, reducing color differences, streaks, or spots, and providing excellent penetration and color uniformity.

Versatile Application: Ideal for textile pretreatment, dyeing, and finishing processes requiring uniform wetting and stable results.

Excellent compatibility: Seamlessly compatible with refining agents, saponifying agents, and softeners in the same dye bath.

Eco-friendly and biodegradable: Meets OEKO-TEX®, ZDHC, and REACH standards.

Technical Specifications

| Property | Specification |

|---|---|

| Appearance | Colorless, transparent liquid |

| Ionicity | Nonionic |

| pH (1% aq. solution) | ~7.0 |

| Solubility | Readily soluble in water |

Recommended Dosage

- Immersion Dyeing: 1–3 g/L (after dilution)

- Pad Dyeing: 1–3 g/L (after dilution)

- Dilution ratio before use: 1:3 to 1:5

Suitable for continuous or intermittent dyeing and finishing processes, ensuring quick wetting (within 1 second) and stable performance.