In textile tingimento e acabamento production, many problems that seem to occur in the dyeing process, but actually the root cause is often in the pré-tratamento process.

As the most fundamental yet but easily underestimated process in the dyeing and finishing process, the stability of pretreatment process directly affects the evenness of fabric dyeing, color reproducibility and the consistency of finished product quality.

For overseas dyeing mills, fabric manufacturers and textile chemical products distributors, systematically understanding the causes of common problems in the pretreatment process and having early control through reasonable selection of auxiliaries and process optimization is an important way to reduce rework rates, shorten delivery time and enhance customer satisfaction.

Common Problems and Troubleshooting Approaches in Pretreatment Process

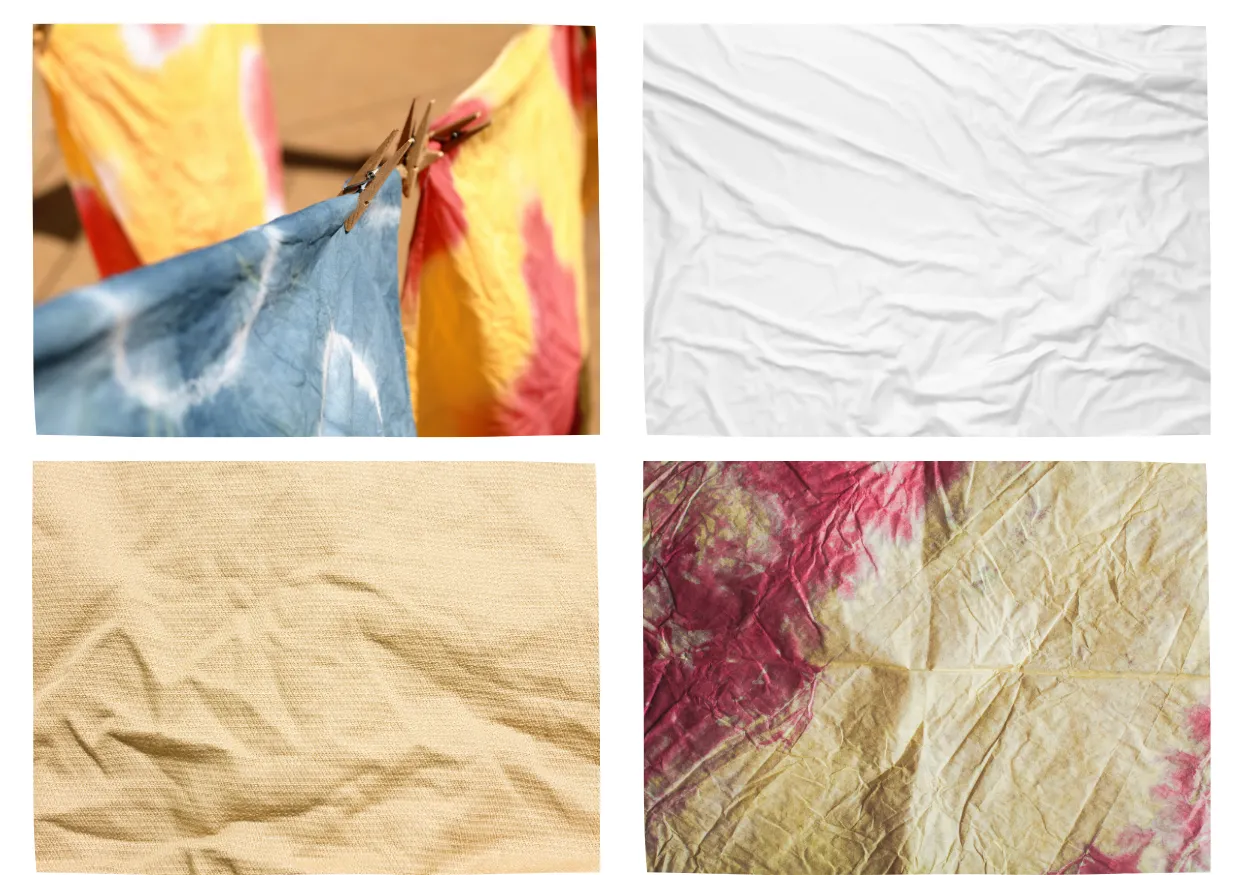

1. Uneven dyeing, dyeing defect and dyeing streaks

Common phenomenon

After dyeing, the fabric shows partial color differences that are uneven, striped or cloud-like, especially more obvious in light color or medium-light color products.

Analysis of Possible Causes

- Em pré-tratamento process, the wetting and penetration are insufficient, and the fabric absorbs liquid unevenly.

- There are residual oil, sizing agent and wax on fabric surface, which prevent the dyes contacting with fibers.

- Desizing is incomplete, leading to partial undyeing.

- Differences in water hardness or uneven distribution of metal ions cause partial abnormal reaction.

Optimization and Improvement Suggestions

- Check the type and actual effect of the penetrating agent and agente umectante, not just the dosage.

- Appropriately strengthen the desizing and soaping processes to ensure that impurities are thoroughly removed.

- Test the water used in the factory and, if necessary, have sequestering treatment or soft water pretreatment to reduce the impact of water quality on process stability.

2. Yellowing or fiber damage after bleaching

Common phenomenon

Whiteness is not stable after bleaching. Yellowing occurs during storage or in subsequent processes, even accompanied by a decrease in fabric strength.

Analysis of Possible Causes

- The decomposition rate of hydrogen peroxide is out of control, and the bleaching reacts too violently.

- The temperature of bleaching is too high, or the bleaching is kept at high temperature for too long time.

- After bleaching, the acid neutralization or water washing is insufficient, the alkali residue is continue to act on the fibers.

Optimization and Improvement Suggestions

- Choose a hydrogen peroxide stabilizer that matches the process conditions, so as to control the reaction rate.

- Set the peak temperature for bleaching reasonably to avoid “over-bleaching”.

- Strictly make neutralization and multi-stage water washing to prevent subsequent problems caused by chemical residues.

3. There are still stains or a pungent smell after soap washing

Common phenomenon

Fabric surface is sticky and has unpleasant smell. Or there appears unstable phenomenon in the subsequent finishing.

Analysis of Possible Causes

- The greasy dirt is not emulsified sufficiently. The degreasing system is lack of stability.

- The degreasing agent or emulsifying agent does not match the actual type of greasy dirt.

- The washing strength is insufficient, and the auxiliaries and dirt are not completely removed.

Optimization and Improvement Suggestions

- Adjust the agente desengordurante and emulsifying agent according to the source of greasy dirt, but not simply increase dossage.

- Appropriately extend the time of soaping or increase the number of washing.

- Under the premise of ensuring the adaptability of equipment, improve the overall rinsing efficiency.

4. Severe foaming affects the running of equipment

Common phenomenon

In pretreatment process, excessive foaming will affect the control of liquid level, convey system or stable running of circulating pump, especially in continuous equipment.

Analysis of Possible Causes

- The foaming control in the auxiliary system is insufficient.

- The formula is not suitable for high-shear or circulating system.

Optimization and Improvement Suggestions

- Preferentially choose low foaming or foaming-controllable auxiliares de pré-tratamento.

- If use defoaming agent, the potential impact on subsequent dyeing and finishing process should be evaluated to avoid new unstable factors.

Practical Suggestions for Energy Conservation And Environmental Protection in The Pretreatment Process

With increasingly strict environmental protection regulations and the continuous rise in energy costs, the pretreatment process has also become an important breakthrough for achieving sustainable production.

- Use biological enzima scouring process

Not only meet the requirements of removing dirt, but also obviously decrease alkali consumption and energy consumption, as well as reduce damage to fibers.

- Optimize the system of rinsing and reusing water

By zonal rinsing, recycling water and monitoring water quality online, improve water use efficiency and reduce overall water consumption.

- Uso auxiliares têxteis with low COD/BOD

Effectively reduce the burden of wastewater treatment. Reduce environmental compliance risks.

- Reduce chemical residues through process optimization

Under the premise of ensuring quality, reduce the total amount of chemicals used to achieve a balance between cost control and environmental responsibility.

Pretreatment: An “Invisible Key” to Determine the Stability of Dyeing and Finishing

Pré-tratamento is often not directly reflected in the appearance of the finished product, but it profoundly affects the evenness and reproducibility of dyeing as well as the finishing effect. From wetting, degreasing to bleaching, the stable control of each link is the foundation for reducing the rework rate, ensuring the delivery time and improving the satisfaction of end customers.

For overseas dyeing mills and fabric manufacturers that mainly focus on the export market, pursue a high first-passyield and long-term stable cooperation, establishing a scientific and replicable pretreatment auxiliary system is a long-term strategy to improve overall competitiveness.

Sobre a BLUELAKECHEM

BLUELAKECHEM has been focusing on researching, developing and producing auxiliares têxteis. We have been serving overseas dyeing mills, weaving mills and textile chemical distributors. Our company provides a product system covering the entire process of pré-tratamento de têxteisincluindo agente umectante, desizing enzyme, agente desengordurante, emulsifying agent, agente sequestrante, hydrogen peroxide stabilizer and low foaming soaping agent, etc.

In addition to supplying product, BLUELAKECHEM also provides customers with technical support from laboratory sample testing to optimization of on-site process formula, assisting factories in enhancing the stability of pretreatment, reducing energy consumption and risk of wastewater discharge. At the same time, our company product line also covers auxiliares de tingimento, functional agentes de acabamento, óleo de silicone e amaciante de silicone. We can provide customers with an integrated textile auxiliaries solution from pretreatment, dyeing to finishing.

If you need to get more detailed technology data, sample support or process suggestion, BLUELAKECHEM can provide targeted solutions and continuous technical support according to fabric types, equipment conditions and production goals.