আধুনিক টেক্সটাইল শিল্পে, fabric coating technology has been widely used in functional fabrics, industrial fabrics, home textiles, medical materials and other fields. In order to achieve performance goals such as softness, waterproofing, stain resistance, breathability, skin friendliness, washing resistance, and antibacterial, how to select fabric coating chemicals scientifically is the core issue that manufacturers need to consider. As a leading textile auxiliaries supplier, BLUELAKECHEM is committed to providing high-performance fabric coating chemical solutions to global customers.

How do fabric coating chemicals work?

Fabric coating chemicals are additives that can form a functional “protective film” on the surface of fabrics. Common uses include dipping, scraping, spraying, etc., to allow chemical components to adhere to and hold to the surface of the fibers, giving the fabric a specific function. For example:

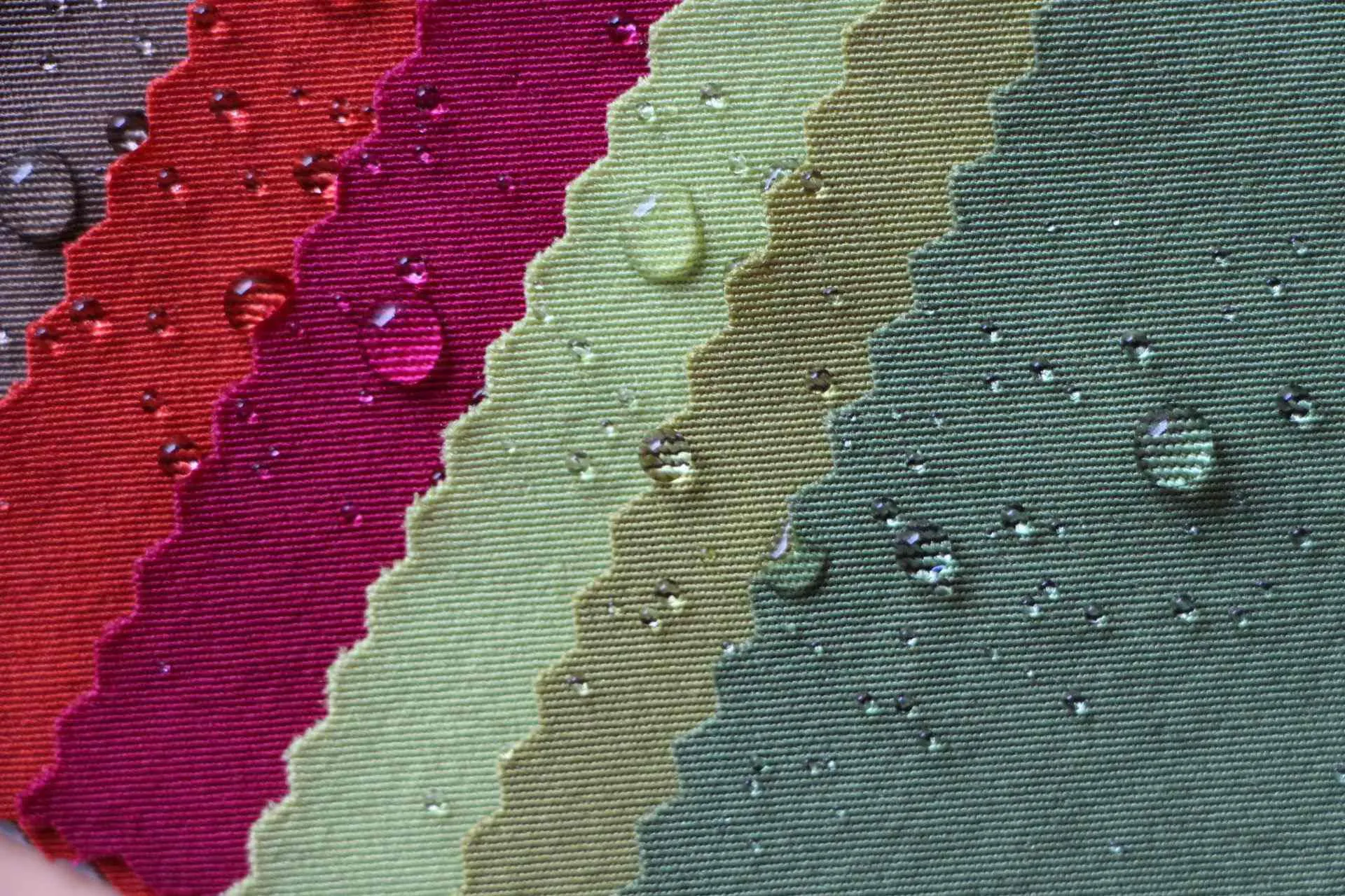

- Waterproof coating: uses silicon-based or fluorine-based molecules to form a hydrophobic structure that makes water droplets impermeable.

- Soft coating: সিলিকন তেল molecules are used to “lubricate” the fiber surface and improve the feel.

- Hydrophilic coating: Hydrophilic groups improve moisture absorption and breathability to enhance skin comfort.

- Antimicrobial coating: forms an antimicrobial active barrier on the surface of the fabric to inhibit the growth of bacteria.

Four key points to consider when selecting a textile coating chemical

- Function first: Clarify the textile effect you want to achieve, soft, waterproof, antibacterial, etc.

- Fabric matching: Different fiber materials are suitable for different additives. For example, hydrophilic silicone oil is recommended for cotton products.

- Process matching: Consider the coating equipment and method, and select the product with appropriate viscosity and stability.

- Environmental protection and certification: whether it needs to pass OEKO-TEX, ZDHC and other standards. Blue Lagoon can provide related supporting products.

Select the fabric coating chemicals according to the target performance

Different functional requirements determine which type of coating chemistry you should use.

| কার্যকরী | Recommended type | Brief description of the principle | Apply effects |

| Soft and smooth | Silicones (amino silicone oils) | The molecular structure forms a lubricating film on the surface of the fiber, reducing the coefficient of friction | Flexible, antistatic, suitable for cotton/polyester fabrics. |

| Waterproof and stain-resistant | Silicone emulsions | The hydrophobic groups repel moisture and oil stains to create a waterproof layer. | Efficient waterproof and stain-resistant, suitable for outdoor fabrics. |

| Hydrophilic and breathable | Hydrophilic silicone oil | Functionally balanced, suitable for sportswear, and denim. | Improve comfort, often used in underwear, baby and children’s clothing. |

| Highly elastic and washable | Block silicone oil | Combining the soft section with the support section enhances the washability. | Functionally balanced, suitable for sportswear, denim. |

| Environmentally friendly and non-toxic | Silicone softener | Water-based emulsion, no harmful volatiles (VOCs). | Passed OEKO-TEX, ZDHC certification. |

Select textile coating chemicals according to the fabric material

Fabric coating chemicals are not a panacea, and different fabric materials have different requirements for coating systems due to different structures and surface activities:

- Cotton/polyester-cotton blend: good adaptability, it is recommended to use amino silicone oil or hydrophilic silicone oil to improve softness and moisture absorption.

- Nylon/Polyester: It is recommended to choose a block silicone oil that is highly compatible with polyester polarity.

- Functional fabrics (such as outdoor and medical): waterproof + antibacterial + durability need to be comprehensively considered, and multi-functional compound solutions are recommended.

ব্লুয়েলাকেচেম can provide textile auxiliaries product portfolio recommendations based on your specific fabric type to ensure uniform adhesion and stable performance of the coating.

Select textile coating chemicals according to the process parameters

Fabric coating is not only a chemical selection but a process-matching process. Common coating methods include dipping, scraping, transfer coating, etc., each process has different requirements for heat resistance, pH adaptability, and emulsion stability of the product.

- Impregnation process: the product emulsion needs high stability, low foam and strong fluidity.

- Scraping method: the coating liquid is required to have moderate viscosity, good spreadability, and easily condensed.

- Post-treatment of heat setting: Coating additives need to be resistant to high temperatures and non-yellowing.

BLUELAKECHEM Product Advantages

High concentration, low yellowing formula, suitable for high-speed impregnation equipment.

Excellent emulsion stability, no stratification after long-term stirring, and avoid nozzle clogging

Excellent compatibility can be used in combination with resins, flame retardants, antibacterial agents and other additives

Our technical team can help customers optimize dosage and coating conditions to achieve a win-win situation for both cost and performance.

Why choose BlLULAKECHEM fabric coating chemical solution

As a reliable fabric coating chemicals supplier, BLUELAKECHEM offers its customers:

A portfolio of high-performance silicones and functional additives.

Technical R&D support, providing customized formula development.

Comply with international environmental regulations (OEKO-TEX, ZDHC, REACH, etc.).

Flexible delivery mechanism to support fast proofing and international logistics services.

Whether you are a garment fabric factory, home textile factory, or garment export enterprise, we can provide you with efficient, stable and environmentally friendly fabric coating solutions. Feel free to contact us for samples and formulation suggestions.