In textile dyeing and finishing, ensuring color consistency and bath stability is essential for high-quality results. However, metal ions like calcium, magnesium, and iron can disrupt dye uptake, cause precipitation, and lead to equipment scaling.

- Calcium and magnesium ions can react with anionic surfactants and certain dyes, reducing brightness and fastness while leaving residues on fabrics and equipment.

- Iron ions may cause yellowing, rust spots, and fiber damage during peroxide bleaching.

A sequestering dispersant, combining metal ion chelation and dispersion properties, offers an effective solution to these challenges. But what exactly is a chelating dispersant—and why is it an essential part of modern textile operations? BLUELAKECHEM, a textile auxiliaries manufacturer, will answer the above questions for you.

Definition and Mechanism of Sequestering Dispersants

A sequestering dispersant is a multifunctional textile auxiliary that:

- Chelates metal ions (e.g., Ca²⁺, Mg²⁺, Fe³⁺, Cu²⁺) to prevent undesirable reactions during dyeing.

- Stabilizes dye dispersion, preventing agglomeration and sedimentation.

Sequestering dispersants based on organophosphate compounds, such as Sequestering & Dispersing Powder 11032 from BLUELAKECHEM, deliver strong complexing ability and excellent bath stability, even under high temperatures and alkaline conditions.

Key Benefits of Sequestering Dispersants in Textile Processing

Improved Dye Uniformity

By binding with interfering metal ions, chelating dispersants ensure consistent dye uptake, preventing color streaks and uneven shades.

Anti-precipitation and Anti-scaling

In high-temperature or high-pH conditions, metal ions easily form insoluble salts. Chelating dispersants inhibit this process, keeping the system clean and protecting both fabric and machinery.

Enhanced Dispersion Stability

In pigment dyeing and printing, dispersants maintain fine particle distribution, preventing flocculation and ensuring smoother surface finishes.

Extended Equipment Lifespan

By minimizing scale and residue buildup, chelating dispersants reduce maintenance needs and prolong equipment service life.

How to Choose the Right Sequestering Agent: 5 Key Criteria

With so many options on the market, selecting the right chelating dispersant can be challenging. Here are five essential factors to consider:

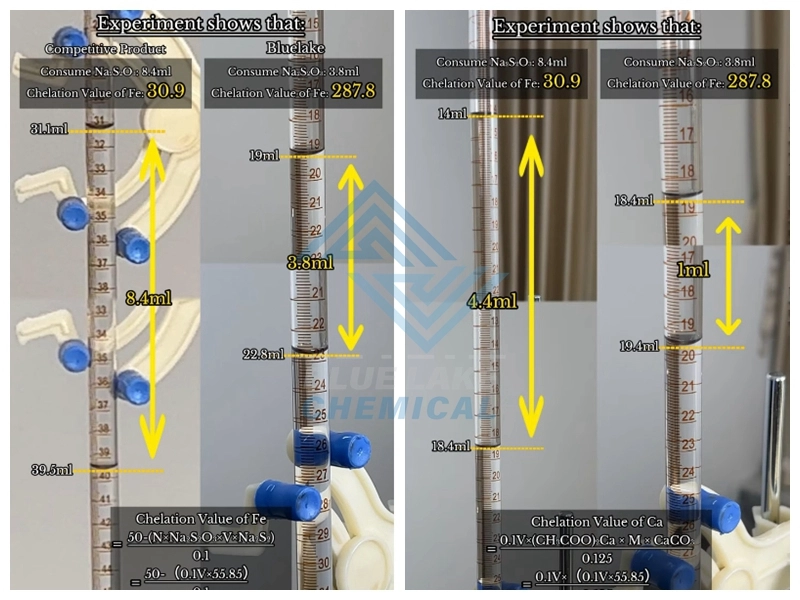

1. Chelation Value of Key Metal Ions

Check the chelating strength against calcium, iron, and magnesium ions. A higher chelation value means stronger binding ability and better control of metal contaminants.

2. Dispersing Performance

Observe whether the product can prevent dye coagulation or sedimentation. Good dispersibility helps maintain bath stability and reduces dye spots or staining issues.

3. Environmental Safety

Choose chelating agents that are free from EDTA, DTPA, and other banned substances. Opt for biodegradable products that meet global environmental standards such as ZDHC and OEKO-TEX.

4. Phosphate-Free Formulation

Select products that do not contain phosphates. These formulations reduce the environmental impact of wastewater and support sustainable manufacturing practices.

5. Functional Versatility

Ensure the chelating agent is effective across multiple processes, such as scouring, bleaching, dyeing, printing, and soaping, and is proven to improve water softening, scale removal, and dye uptake.

Wide Range of Applications

Sequestering dispersants are suitable for various textile processes, including:

- Pretreatment (desizing, scouring, bleaching): to soften hard water and remove metal contaminants.

- Polyester disperse dyeing: to prevent dye precipitation and improve dyeing uniformity.

- Reactive dyeing on cotton: to improve shade reproducibility and prevent streaks.

- Pigment printing: to maintain pigment dispersion and prevent printhead clogging.

- Soaping and finishing: to remove unfixed dyes and minimize redeposition.

Recommended Product: Sequestering & Dispersing Powder 11032

Sequestering & Dispersing Powder 11032 is a non-ionic chelating dispersant powder formulated with organophosphate complexes. It features:

- Excellent thermal, alkali, oxidant, and electrolyte resistance.

- High chelating values, proven in titration experiments.

- Strong dye dispersion stability.

- Phosphate-free, EDTA/DTPA-free, and biodegradable.

- Suitable for scouring, bleaching, dyeing, printing, soaping, and finishing.

Sustainability and Eco-compliance

As sustainable practices become a priority in the textile industry, modern sequestering dispersants are increasingly:

- Free from EDTA, NTA, and other non-biodegradable components.

- Highly biodegradable.

- Fully compliant with major environmental certifications (ZDHC, OEKO-TEX).

Choosing eco-friendly auxiliaries not only helps meet regulatory standards but also lowers wastewater treatment costs and environmental impact.

Conclusion

Sequestering dispersants have evolved into an essential component of quality textile production, helping ensure dye bath stability, fabric cleanliness, and overall process efficiency. Whether you are working with cotton, polyester, or blends, a reliable chelating dispersant like Sequestering & Dispersing Powder 11032 can greatly improve your dyeing performance and operational stability. For technical data or product samples, feel free to contact us. We offer tailored, efficient, and sustainable solutions for textile manufacturers worldwide.