In polyester-cotton blended fabrics such as CVC and TC, reactive dyeing and printing processes are commonly used to achieve bright and vibrant colors on cotton fibers. However, one frequent challenge is unwanted staining on the polyester component. Although reactive dyes are designed to bond with cellulose (cotton), they may be physically adsorbed onto polyester fibers during the dyeing or printing process, resulting in white area staining, background discoloration, or color defects in the final product.

This is where a polyester dye-resist agent plays a critical role. By protecting the polyester portion of the fabric from dye contamination, it ensures clean separation of colors, enhances appearance, and reduces rework.

Common Issues in Polyester Dyeing

During the reactive dyeing or printing of cotton in blended fabrics, the polyester part may unintentionally pick up reactive dyes. This leads to several issues:

- White Ground Staining: Intended white or light areas on polyester appear tinted or dull.

- Color Bleeding: Dyes spread from printed areas to non-target regions.

- Uneven Background: Polyester absorbs different amounts of dye, causing background color inconsistencies.

- Lower Color Fastness: Dye not properly fixed on polyester may bleed during washing.

These problems directly impact the quality, visual appeal, and marketability of the final textile products.

How Does Polyester Dye-Resist Agent Work?

Polyester dye-resist agents primarily function through the following mechanisms:

- Surface Protection: Adsorbs onto the polyester surface, forming a temporary hydrophilic layer that blocks dye penetration.

- Dye Blocking: Prevents reactive dyes from interacting or adhering to polyester, especially in white or light background areas.

- Synergistic Cleaning: Enhances performance during reduction cleaning and soaping by assisting in the removal of unreacted dyes.

- Improves Appearance: Maintains sharp print edges and white clarity in background areas.

Solution: BLUELAKECHEM Polyester Dye-Resist Agent 23717

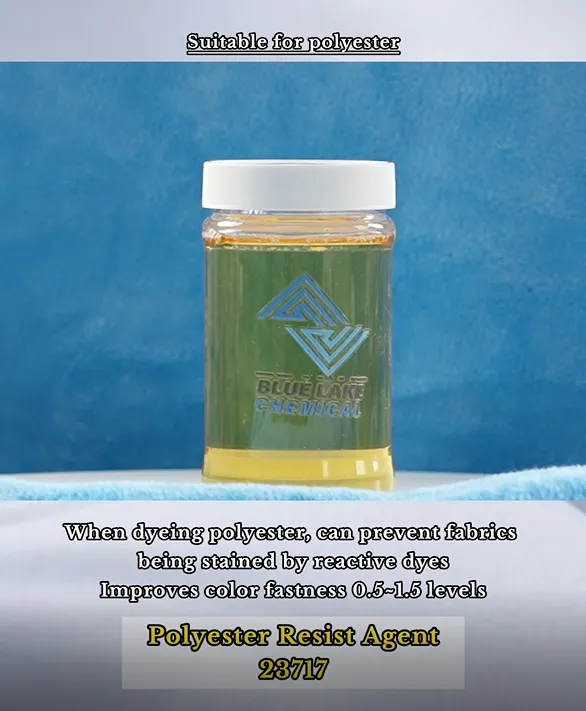

BLUELAKECHEM 23717 is a specially formulated polyester anti-staining agent designed for use in reactive dyeing or printing processes of cotton-polyester blended fabrics. It forms a temporary, protective barrier on the polyester surface, effectively blocking reactive dye molecules from being adsorbed onto polyester fibers.

Appearance: Light yellow to yellow transparent liquid(the color will gradually lighten with extended storage time)

Application Scope: For protecting polyester in polyester-cotton blended fabrics during reactive dyeing or printing. S

Features:

- Excellent anti-staining performance on polyester in reactive dye systems

- No impact on color strength or brilliance of dyed cotton

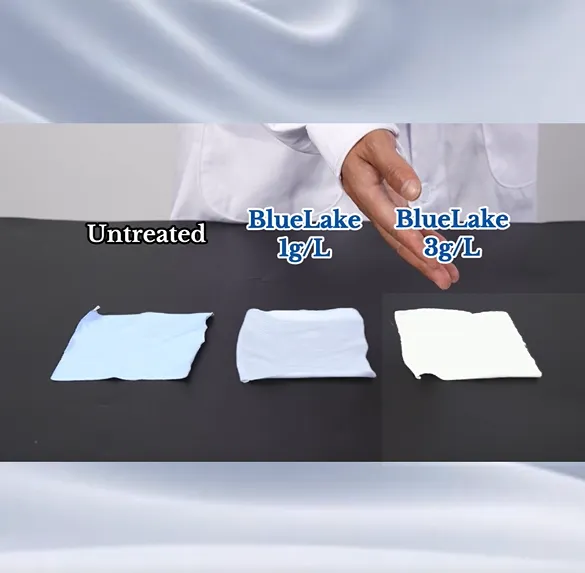

- Improves color fastness by 0.5 to 1.5 grades

- Formaldehyde-free, APEO-free, compliant with Oeko-Tex and ZDHC

- Compatible with reduction cleaning and soaping agents

- Easy to use in existing dyeing/printing workflows

Recommended Application Process

For best results, incorporate 23717 during the reduction cleaning stage after reactive dyeing or printing:

Process Flow: Dyeing→Reduction Cleaning (alkali+sodium hydrosulfite+dye-resist agent) →Hot Water Wash→Acid Wash→Soaping→Water Wash→Drying

Reduction Cleaning Formula:

- Sodium Hydrosulfite: 2 g/L

- Soda Ash: 1 g/L

- Polyester Dye-Resist Agent: 1- 3 g/L

Conditions:

- Temperature: 80°C

- Time: 15 minutes

- Liquor Ratio: 1:10

Note: The dosage can be adjusted according to the actual situation of different equipment.

Conclusion

In the competitive world of textile dyeing, quality control and color precision are essential. By using BLUELAKECHEM Polyester Dye-Resist Agent 23717, manufacturers can eliminate polyester background staining during reactive dyeing or printing, resulting in cleaner finishes, brighter colors, and fewer quality complaints.

Contact us today for technical guidance, sample requests, or pricing details.