Ultra Soft Silicone Oil Emulsion, Anti-yellowing Finishing Agent for Cotton Viscose

BLUELAKECHEM Silicone Oil Emulsion is a modified block silicone oil designed for cotton, viscose, and blended fabrics. It provides an ultra-soft handle, excellent smoothness, and outstanding anti-yellowing performance, making it the ideal finishing agent for high-quality and light-colored textiles. Contact us to request a technical data sheet, free samples, or expert advice for your bulk fabric finishing needs.

Số hiệu mẫu70868

Từ Nhà sản xuất hóa chất dệt may

Mô tả về hóa chất dệt may

Tính năng của nhũ tương dầu silicon:

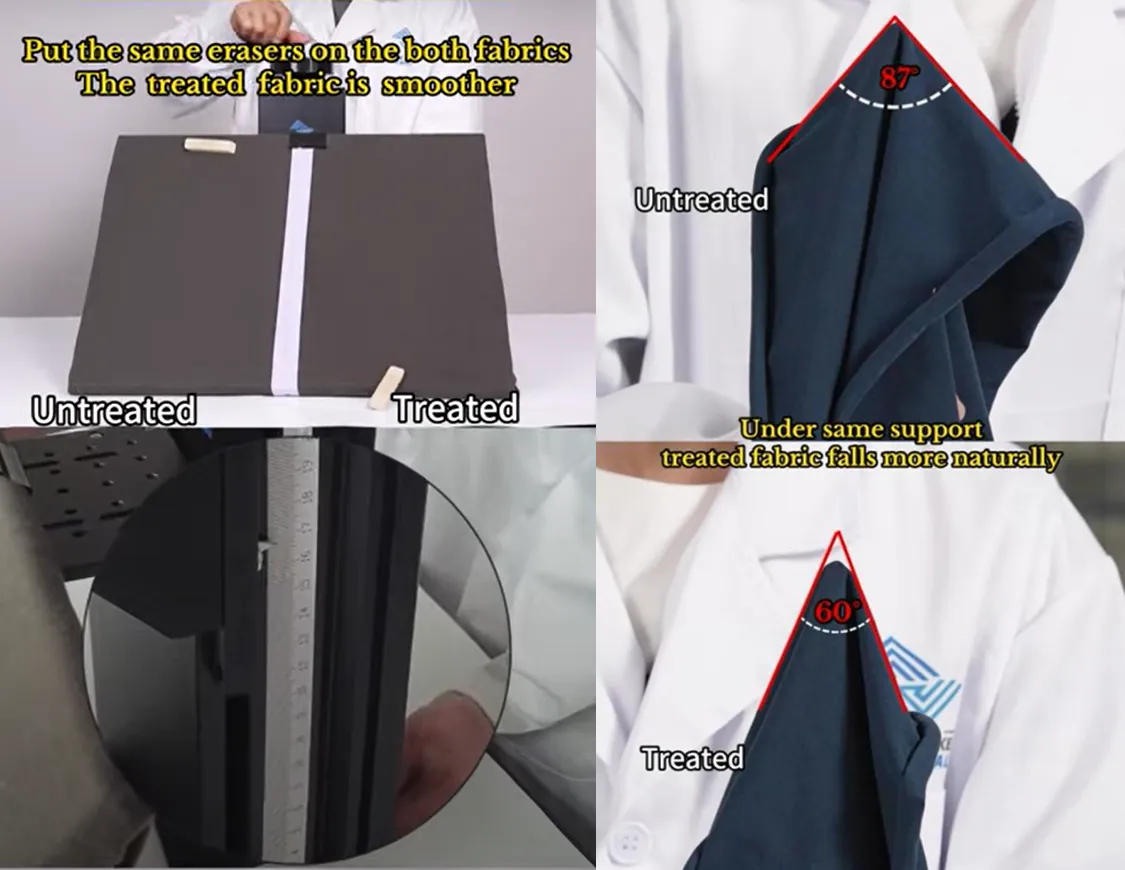

Excellent Softness & Smoothness: Gives fabrics a soft, fluffy, and premium handle without greasiness or stickiness.

Anti-yellowing Performance: Special formulation prevents yellowing even after high-temperature processing or long-term storage, ideal for light-colored and white fabrics.

High Emulsion Stability: Maintains stable dispersion and uniform finishing performance during production.

Easy to Emulsify: Can be processed using a wide range of equipment, making it easily integrative into a wide range of manufacturing processes.

Eco-friendly and Non-toxic: Silicone oil emulsion is environmentally friendly and meets strict safety standards for textiles in direct contact with skin.

Ứng dụng đa năng: It is applied to natural fibers such as cotton and cellulose, synthetic fibers, and blends.

Application Fields

- Soft finishing of fabrics: Cotton, viscose, polyester, and blended fabrics

- Đồ dệt gia dụng: Towels, bedding, upholstery

- Baby and premium fabrics: Provides tender yet durable softness

- Industrial textiles: Enhances handle for water-repellent or functional fabrics

- Heat-sensitive fabrics: Low-yellowing property suits light-colored or delicate textiles

Silicone Oil Emulsion Technical Parameters:

| Mặt hàng | Specification |

| Hình thức | White or milky emulsion |

| Độ ion | Cation yếu |

| pH (1% aqueous solution) | 6.0–7.0 |

| Độ tan | Easily emulsified in water |

Recommended Application Methods

Padding Process:

- Light fabrics: 10–20 g/L

- Heavy fabrics: 20–30 g/L

- Stenter: 160–170 °C × 60–90 s

- pH: 6.0–7.0

Exhaust Process:

- Dosage: 1.0–3.0% (o.w.f)

- Tỷ lệ tắm: 1:20

- Temperature: 40–50 °C × 10–20 min → Dewater → Dry at 100–120 °C

Can be used together with other softeners. Perform compatibility testing before blending.