In the functional finishing of nylon (polyamide) fabrics, a common challenge arises: poor moisture absorption and discomfort during wear. Nylon lacks hydrophilic groups in its molecular structure, making it prone to stuffiness, stickiness, and poor wicking, especially in sportswear and intimate apparel.

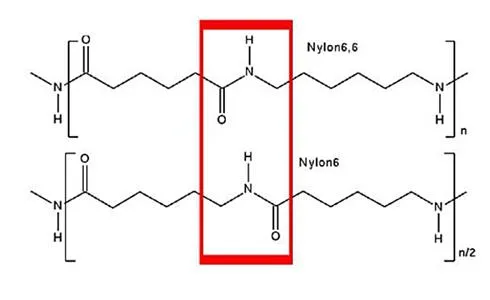

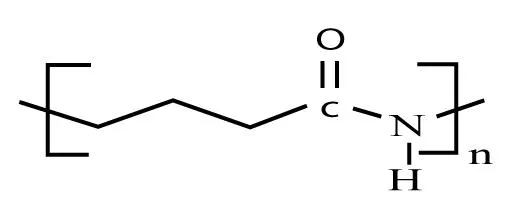

To address this issue, BLUELAKECHEM has introduced a professional product that incorporates amino-modified components into the hydrophilic agent. The amino-modified components can produce a similar solubility effect with nylon. Only when the hydrophilic agent can achieve similar solubility with the fabric can a more durable hydrophilic effect be realized.

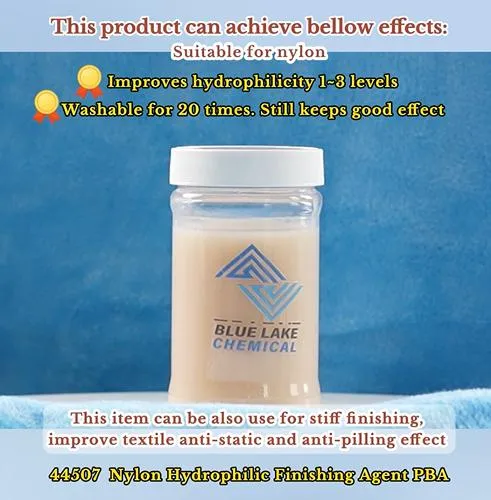

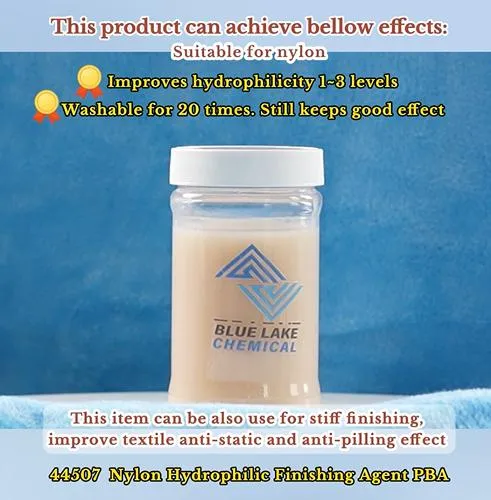

Nylon Washable Hydrophilic Finishing Agent 44507

This agent not only improves hydrophilicity by 1–3 levels but also withstands over 20 washes, offering both comfort and durability.

Why Nylon Needs Hydrophilic Finishing?

Nylon fabrics naturally lack hydrophilic groups, resulting in:

- Low moisture absorption

- Poor sweat-wicking performance

- Sticky and uncomfortable feeling while wearing

This limits their use in functional or high-performance textiles, unless they are treated with a proper hydrophilic agent.

What makes our Hydrophilic Finishing Agent Different?

Our hydrophilic finishing agent contains amino-modified components that establish intermiscibility with nylon molecular chains, creating strong, durable bonding and lasting hydrophilic effects.

Molecular Affinity = Longer Effect

The amino groups interact with the polyamide backbone, allowing the agent to anchor effectively, making it:

- More durable to washing

- Uniformly bonded to the fiber surface

- Compatible with common finishing setups

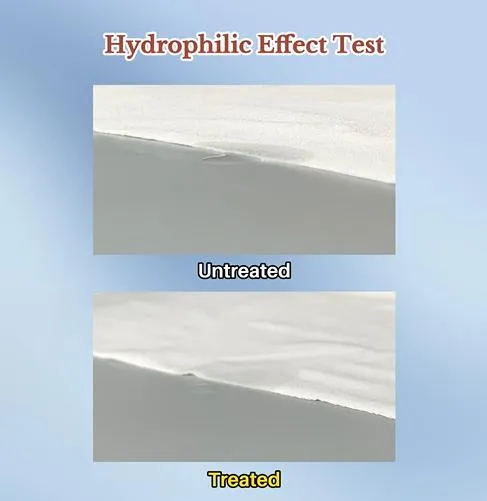

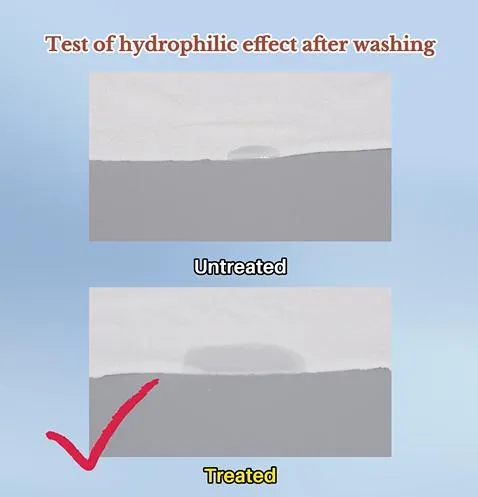

Real Lab Testing Results

1. Hydrophilicity Test Before and After Treatment

- Fabric: White nylon fabric

- Dosage: Standard application (low dosage)

- Test Method: Drop test (contact angle method)

| Sample | Water Absorption Speed | Improvement |

| Untreated | Slow absorption | — |

| Treated | Fast penetration | Improved by 2 levels |

Conclusion: Even with a small dosage, treated fabrics show significant improvement in hydrophilicity, providing a noticeably cooler and quicker-drying effect.

2. Wash Fastness Test –20 Machine Washes

Condition: Machine washed 20 times under the same temperature and detergent conditions

| Sample | Post-wash Performance | Result |

| Untreated | No improvement | Poor |

| Treated | Still highly hydrophilic | Excellent |

Result:

Treated fabrics maintained strong wicking and hydrophilic behavior, better than untreated, and even outperformed competing brands.

Key Features at a Glance

- Improves nylon fabric’s hydrophilicity by 1–3 levels

- Maintains its effect after 20+ home launderings

- Enhances sweat-wicking and soil release ability

- Contains amino-modified active units for durability

- Low dosage, cost-effective solution

- Suitable for sportswear, underwear, outerwear, and more

Designed for Global Textile Applications

Whether you’re a dyeing/finishing mill, a functional apparel factory, or a chemical distributor supplying nylon solutions, 44507 helps you:

- Meet the rising market demand for performance nylon

- Reduce reprocessing and customer complaints

- Upgrade product lines with value-added comfort

- Offer differentiation for buyers seeking washable hydrophilic finishes

Free Sample Available

Appearance: Light yellow to light brown liquid

Ionicity: Weak cationic

pH value: 4.0±

1.0 (1% aqueous solution)

Solubility: Soluble in water

BLUELAKECHEM offers free lab testing samples and technical guidance for international partners. Whether you are testing for R&D, sampling for OEM clients, or seeking to upgrade your product offering, we’re here to help.